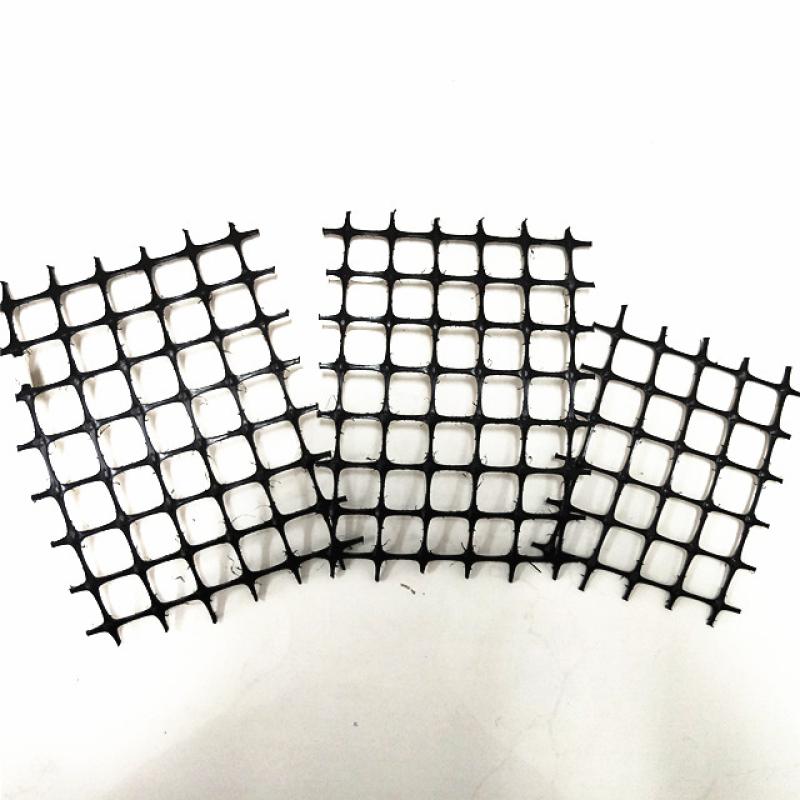

Product DetailsSteel plastic geogrid is characterized via using high corrosion resistance and fantastic placed on resistance.

Связаться сейчас

Product DetailsSteel Plastic Geogrid is characterized by high corrosion resistance and excellent wear resistance. It is made of high strength steel coated with virgin polyethylene or high density polyethylene by special ultrasonic welding technology. Steel plastic geogrid reinforcement is weld into longitudinal and latitudinal staggered intervals in the same planner, different wire mesh diameter and root number can be fabricated according to project reinforcement force requirement.

Связаться сейчас

Product DetailsSteel Plastic Geogrid is characterized by high corrosion resistance and excellent wear resistance. It is made of high strength steel coated with virgin polyethylene or high density polyethylene by special ultrasonic welding technology. Steel plastic geogrid reinforcement is weld into longitudinal and latitudinal staggered intervals in the same planner, different wire mesh diameter and root number can be fabricated according to project reinforcement force requirement.

Связаться сейчас

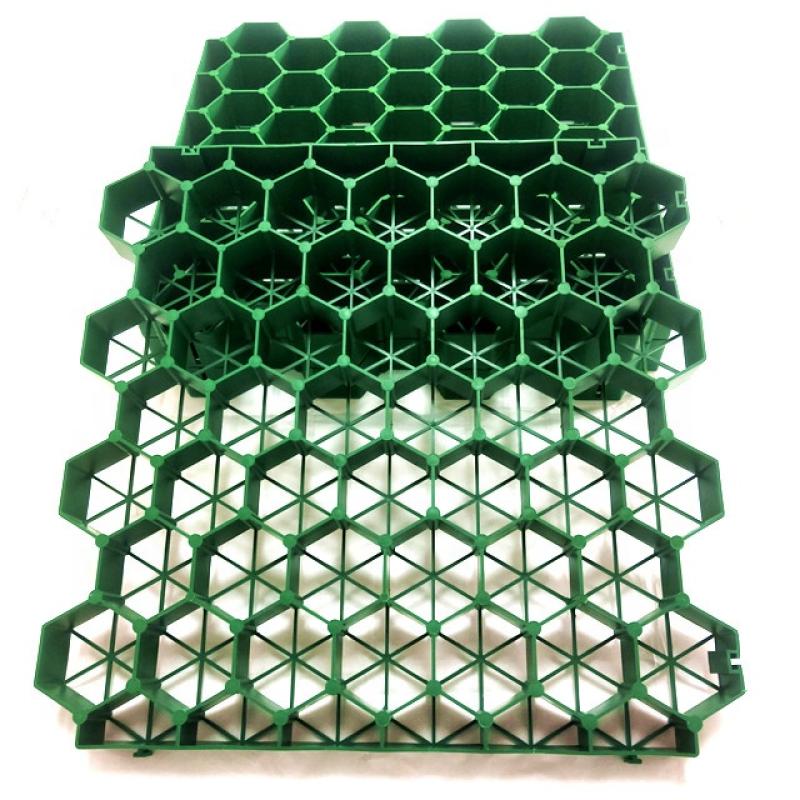

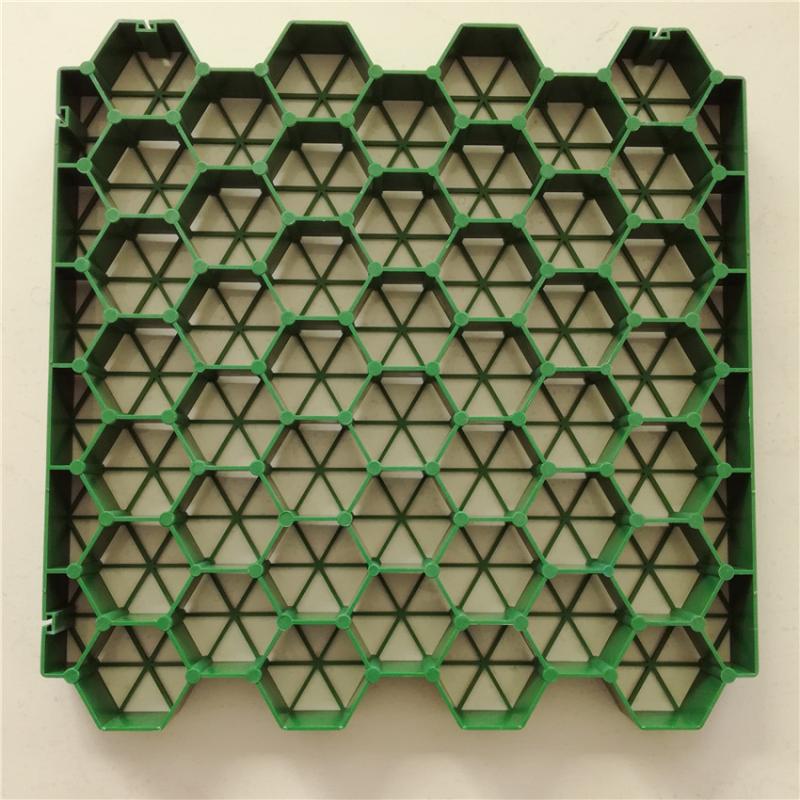

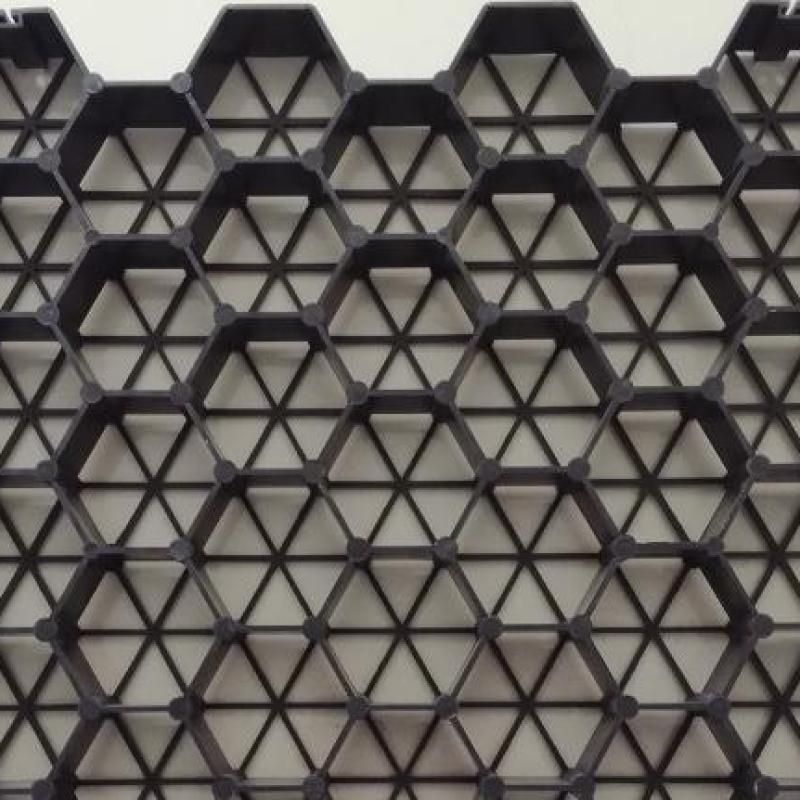

Product DescriptionPlastic grass paving grid is made from HDPE(high-molecular polyethylene)with fiber and age resistor, using high pressure to inject plastic to form bee nestlike shaped shell,with stereo space and support level.

Связаться сейчас

Plastic Grass Paving Grid 50mm for Lawn Parking Lot DrivewayPlastic grass paving grid is made from PP or HDPE (high-molecular polyethylene) with fiber and age resistor, using high pressure to inject plastic to form bee nest-like shaped shell, with stereo space and support level. It’s widely used in parking lot, fire exit, fire climbing surface, pavement etc.

Связаться сейчас

Product DetailsInside the concrete combination, add proper amount steel fiber may be mixed into a type of special jetting as well as casting concrete, specifically metal fiber bolstered concrete.In comparison with fashionable concrete, metallic fiber concrete has high-quality development in tensile strength, flexural strength, abrasion resistance, effect resistance, fatigue resistance, sturdiness, crack resistance and antiknock overall performance, due to the fact huge quantity of very minute steel fiber is frivolously dispersed within the concrete and has a massive contact place with concrete

Связаться сейчас

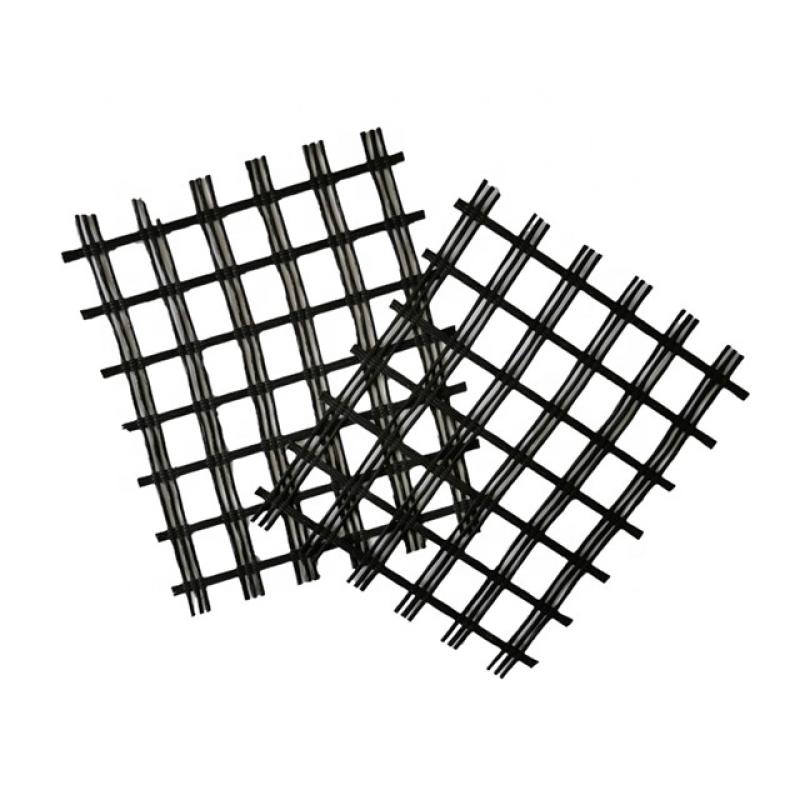

Product DetailsMetal plastic geogrid is characterised by using high corrosion resistance and incredible put on resistance.

Связаться сейчас

Product DetailsMetal plastic geogrid is characterised by using high corrosion resistance and incredible put on resistance.

Связаться сейчас

Product DetailsMetallic plastic geogrid reinforcement can correctly complements the bearing ability of foundation and stops the soil from lateral displacement because of its excessive friction coefficient and the bearing capability.

Связаться сейчас

Product DetailsSteel Plastic Geogrid is characterized by high corrosion resistance and excellent wear resistance. It is made of high strength steel coated with virgin polyethylene or high density polyethylene by special ultrasonic welding technology.Steel plastic geogrid reinforcement is weld into longitudinal and latitudinal staggered intervals in the same planner, different wire mesh diameter and root number can be fabricated according to project reinforcement force requirement.

Связаться сейчас