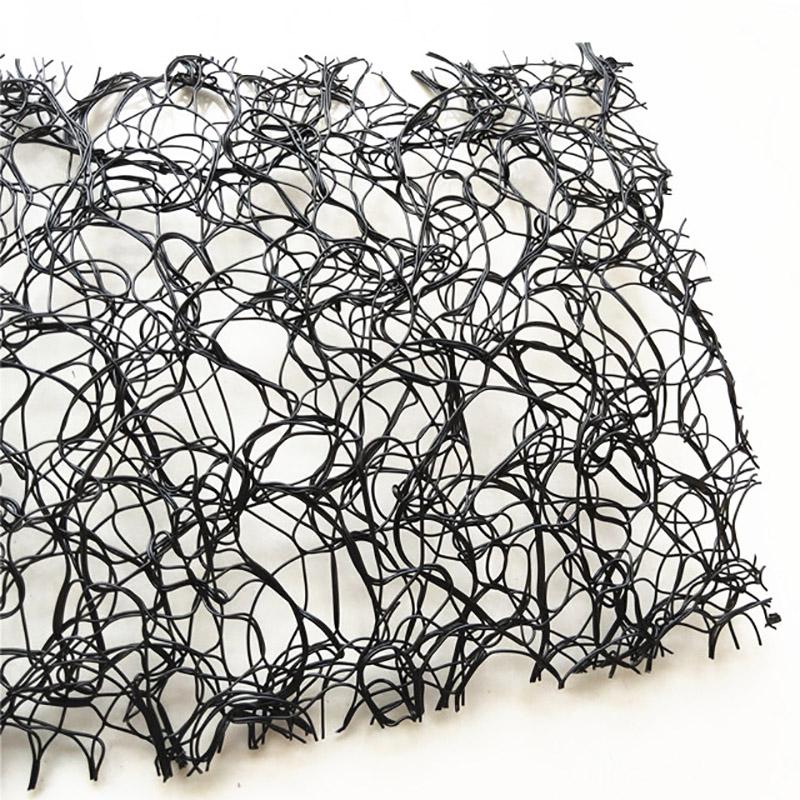

Product DetailsDrainage sheet mat is made of plastic core and filtering cloth.In the state of hot melting,it is formed into three-D network structure.It has two shapes:rectangle and round.This kind of pipe has some advantages:good drainage,high pressure resistance,light weight,so it is very popular in some projects.ParameterPropertiesCDK-05CDK-06CDK-08CDK-10CDK-15CDK-20Thickness568101520Pressure Resistance250Kpa280KpaStretch Rate≥6.0Kn/mElongation Percentage≥40%Porosity 80-90%Horizontal Hydraulic Conductivity200Kpa,≥5.0x10-3 M²/sFeature* Flexible and durable* High Tensile Strength and Low Elon

Связаться сейчас

Product informationThe strengthened geomat is pp mesh mat composited with twine mesh, this is galvanized in case of abrasion manipulate.The form allows enough location for keeping the soil and grass growing.

Связаться сейчас

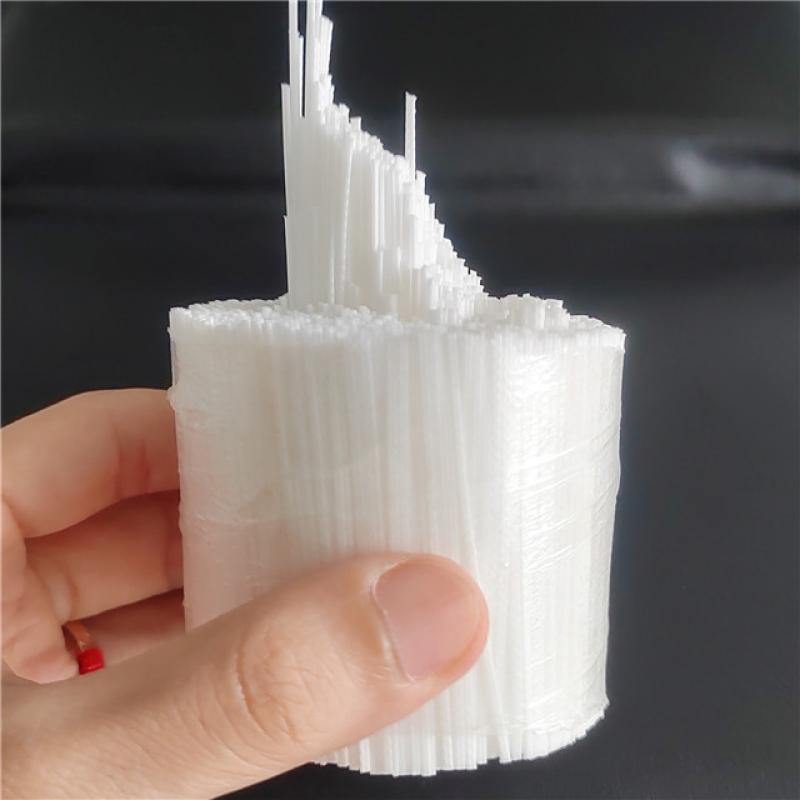

Concrete Fiber Polypropylene PP Fiber MeshPolypropylene mesh fiber is a kind of polypropylene particles as raw material, which is specially processed and treated. Add to the concrete base material. After stirring, the monofilament fiber or mesh structure fiber is fully opened, forming a chaotic support system inside the concrete. Polypropylene pp fiber mesh can effectively control the early plastic shrinkage and settlement cracks of concrete and cement mortar.

Связаться сейчас

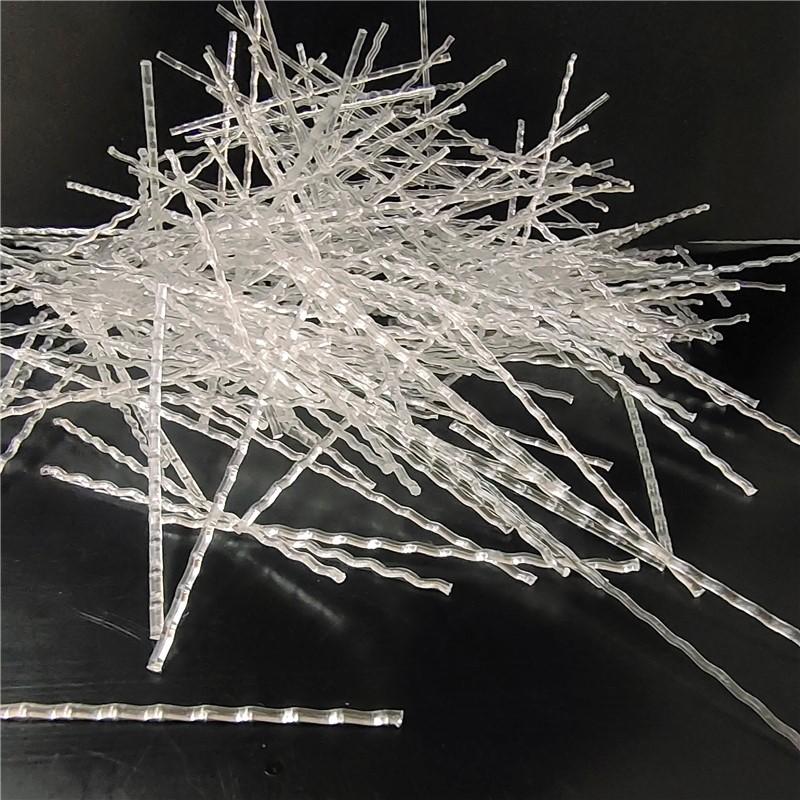

Application Of High Performance Polypropylene Twisted FiberTwisted fiber is a kind of high performance fiber used in construction engineering. When the polypropylene twisted fiber macro pp fiber added to concrete, can significantly improve the crack resistance, permeability resistance, wear resistance, impact resistance, bending resistance and bending resistance of concrete.

Связаться сейчас

With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.Application1. Surface of road and highway.2.

Связаться сейчас

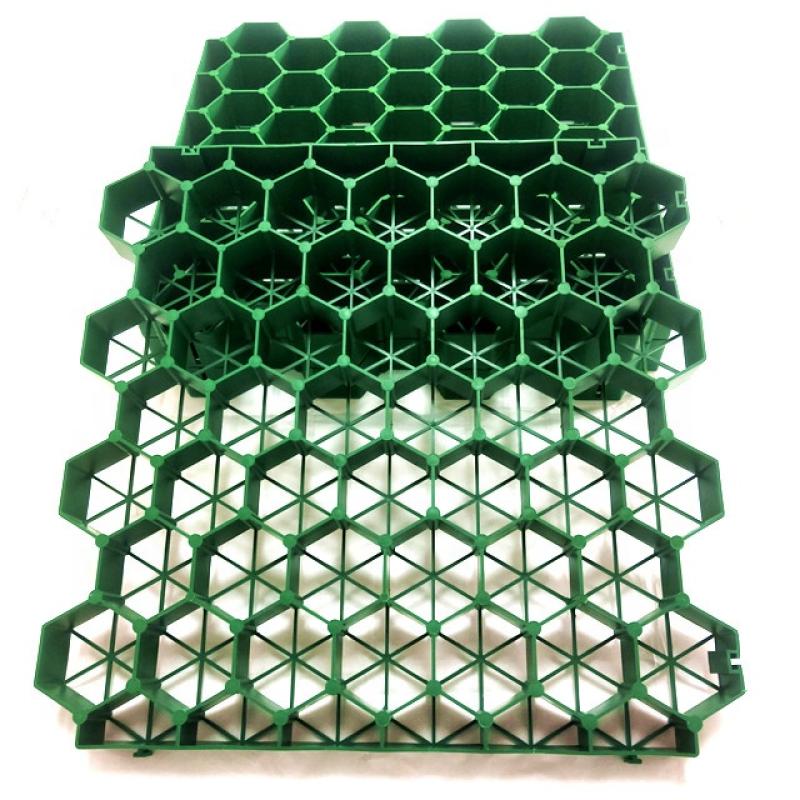

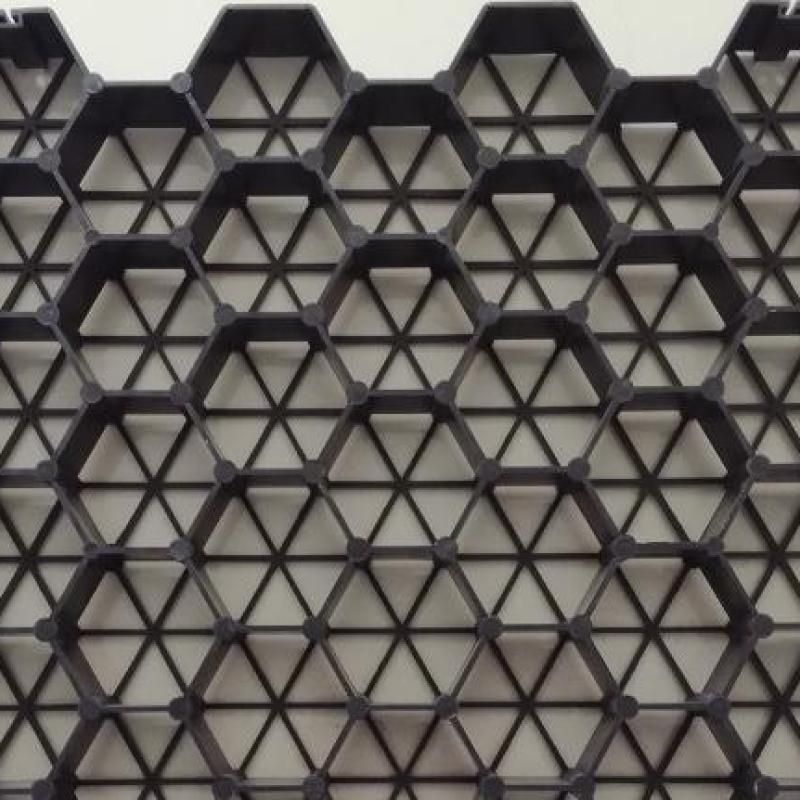

Product DescriptionPlastic grass paving grid is made from HDPE(high-molecular polyethylene)with fiber and age resistor, using high pressure to inject plastic to form bee nestlike shaped shell,with stereo space and support level.

Связаться сейчас

Anti-cracking Polypropylene Fiber PP Macro Fiber Anti-cracking polypropylene fiber pp macro fiber is called Polypropylene plastic steel fiber (toughened polypropylene synthetic macro fiber) to fill the blank between steel fiber,the surface of the fiber is rough, uneven, is a new type of reinforcement, toughening material.The main purpose of adding anti-cracking fiber to the concrete is: it has the advantages of strong anti-cracking, anti-impact performance, high wear resistance, good affinity with cement, can increase the strength of components, extend the service life, and overcome the s

Связаться сейчас

What Is Concrete Polypropylene Macro FiberConcrete fiber is also called polypropylene macro fiber.It is widely used in lots of construction projects. It is a kind of high-performance fiber specially used for concrete and mortar, which can effectively control the micro-cracks caused by plastic shrinkage, dry shrinkage, temperature change and other factors of concrete and mortar, prevent and inhibit the formation and development of concrete primary cracks, thus greatly improving the crack and permeability resistance of concrete and mortar, and increase the toughness of concrete.

Связаться сейчас

Luke PP Dewatering Bags Geotube BagThe silt dewatering pipe bag is usually woven from a special polymer material and has a filter structure. The equivalent aperture design of the dewatering geotube bags allows it to effectively filter moisture while resisting the long-term effects of UV rays, guaranteeing its durability . Sludge dewatering agent is added to the inside of the pipe bag to promote the separation of mud and water. The water seepage through the filter structure of the pipe bag, while the sludge remains in the pipe bag .

Связаться сейчас

Product DetailsFiberglass geogrid is made of excellent reinforcement type non-alkali glass fiber yarn which is weaved into base material by using foreign advanced warp knitting directional structure. Fiberglass geogrid can make full use of yarn textile strength to improve its chemical performance, high tension resistance, tearing resistance and creep resistance. Fiberglass geogrid system is widely used to reinforce road surface, prevent highway harm such as crack and rut from occurring, solve the problem that asphalt road surface is difficult to reinforce.ParameterItem

Связаться сейчас