Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Связаться сейчас

Synthetic PP Staple Fiber Polypropylene PP Macro Fiber for Concrete EngineeringProduct Details Concrete pp fiber is made via a hundred% virgin polypropylene,adopting unique manufacturing manner to make excessive strength bundle monofilament fiber. While the fiber is put into the concrete,concrete (or mortar) can effectively manipulate concrete (or mortar) Micro-cracks that's resulting from plastic shrinkage, temperature modifications and different elements, to save you and Inhi

Связаться сейчас

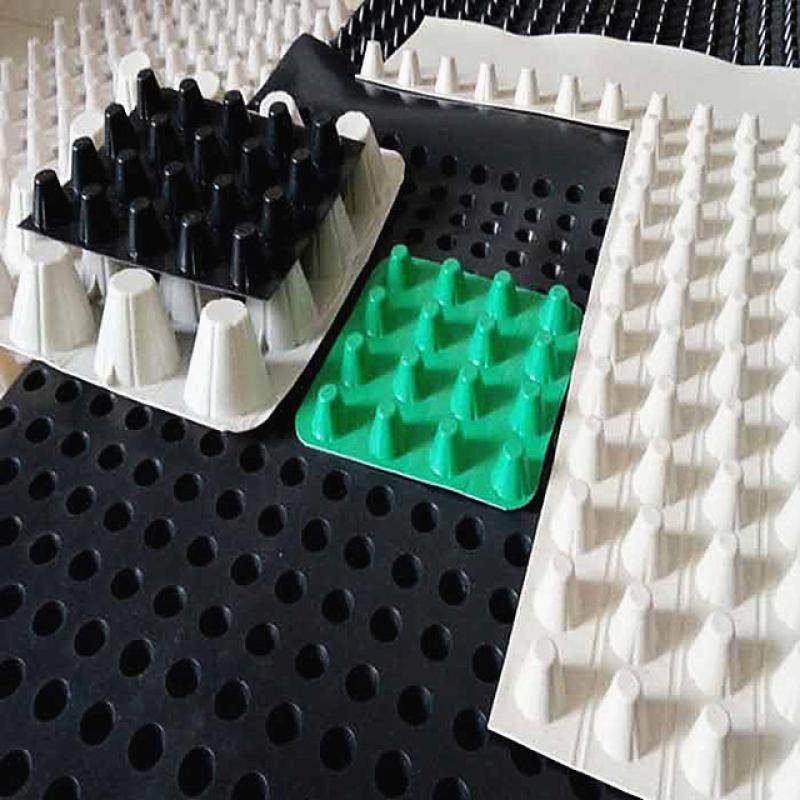

Product DetailsComposite drainage net is made from geonet bonding two layers of geotextile which combines the properties of geotextile filtration and geonet drainage and protection,providing complete“inverted filter drainage to protect”effect.Drainage nets core is extruded by high density polyethylene raw materials adding carbon black and ultraviolet and antioxidant stabilizer.The interlaced net forms into a drainage channel which has good vertical drainage properties.ParameterTest PropertiesUnitDN750DN1000DN1300DN1600Unit weightG/M²750100013001600ThicknessMM5677.6Hydraulic ConductivityM/SK*10

Связаться сейчас

Product DetailsComposite drainage net is made from geonet bonding layers of geotextile which combines the homes of geotextile filtration and geonet drainage and safety,providing entire“inverted clear out drainage to shield”effect.drainage nets center is extruded by way of excessive density polyethylene uncooked materials adding carbon black and ultraviolet and antioxidant stabilizer.the interlaced net office work right into a drainage channel which has fantastic vertical drainage residences.ParameterTest PropertiesUnitDN750DN1000DN1300DN1600Unit weightG/M²750100013001600ThicknessMM5677.6

Связаться сейчас

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Связаться сейчас

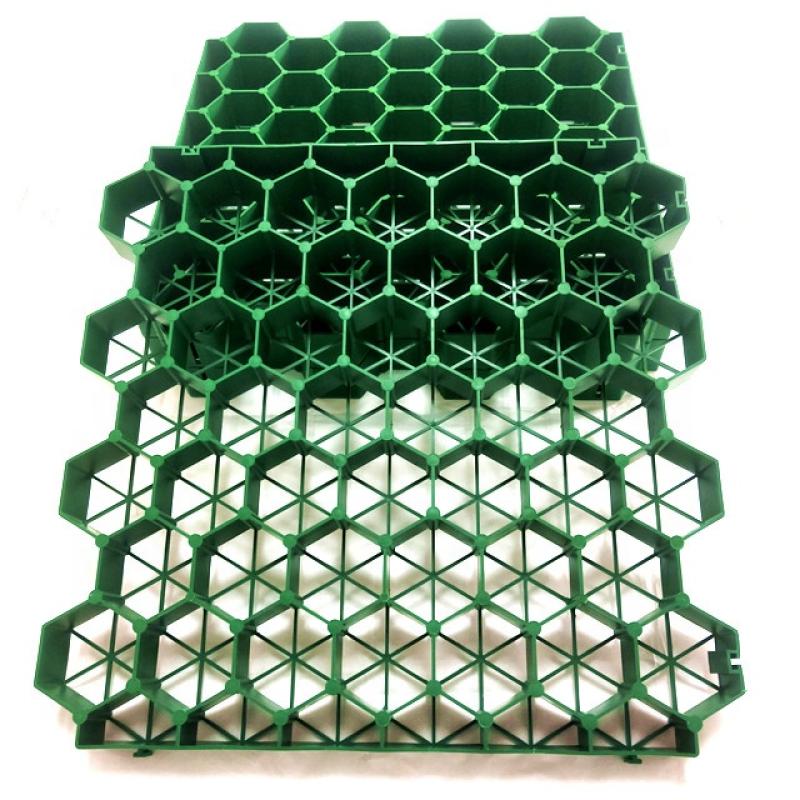

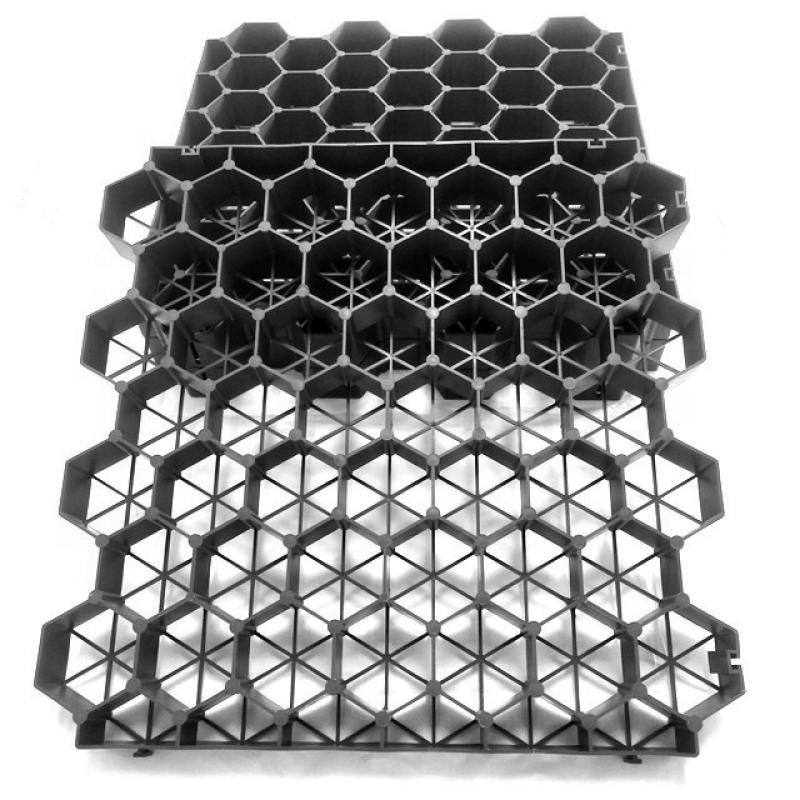

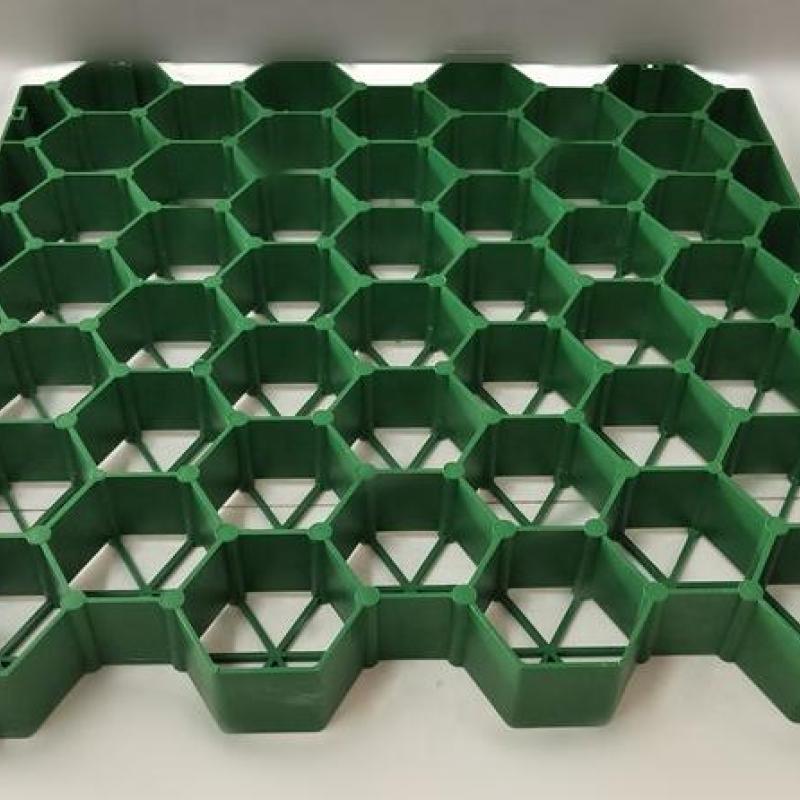

GRASS PAVERs are environmentally friendly. They are made from recycled plastic and allow the drainage of storm water back into the underground soil rather than into storm drains. This helps keep your property hydrated and reduces runoff into local sewer systems. 1. Pervious Load Bearing Surface 2. Stormwater Pollution Filtration and Treatment 3. Airborne Dust Capture and Retention 4. Heat Energy Reflection Reduction, “Cool” Surface 5. Tree Growth within Parking Areas 6. 92% Void Space for Healthy Root Development 7.100% Real Grass Coverage 8.

Связаться сейчас

GRASS PAVERs are environmentally friendly. They are made from recycled plastic and allow the drainage of storm water back into the underground soil rather than into storm drains. This helps keep your property hydrated and reduces runoff into local sewer systems. 1. Pervious Load Bearing Surface 2. Stormwater Pollution Filtration and Treatment 3. Airborne Dust Capture and Retention 4. Heat Energy Reflection Reduction, “Cool” Surface 5. Tree Growth within Parking Areas 6. 92% Void Space for Healthy Root Development 7.100% Real Grass Coverage 8.

Связаться сейчас

Product Details Twisted package pp fiber is developed for replacement of metallic fiber. With polypropylene as its raw material,it's far produced by way of special drawing twisting and surface remedy. Compared with metallic fiber, it has benefits of acid, alkali resistant, first rate tensile, clean dispersing, comfort for creation and no harm to the combination system. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwi

Связаться сейчас

0.75mm To 3.0mm Anti-seepage HDPE GeomembraneGeomembrane also known as impermeable geomembrane,polyethylene geomembrane,etc.It is a kind of polymer material with excellent impermeable properties.It made from high grade polyethylene raw material,adding carbon black,antioxidant,anti-aging and UV resistance component.It adopted the first class automatic production equipment and three-layer pressing technology.It is widely used in water conservancy, construction, environmental protection and other fields.The main functions of geomembrane:The main functions of geomembrane include seepage prevention

Связаться сейчас

Product DetailsComposite drainage net is made from geonet bonding layers of geotextile which mixes the homes of geotextile filtration and geonet drainage and protection,presenting entire“inverted filter drainage to guard”impact.drainage nets core is extruded by high density polyethylene uncooked substances adding carbon black and ultraviolet and antioxidant stabilizer.the interlaced internet paperwork into a drainage channel which has excellent vertical drainage residences.ParameterTest PropertiesUnitDN750DN1000DN1300DN1600Unit weightG/M²750100013001600ThicknessMM5677.6Hydraulic Conducti

Связаться сейчас