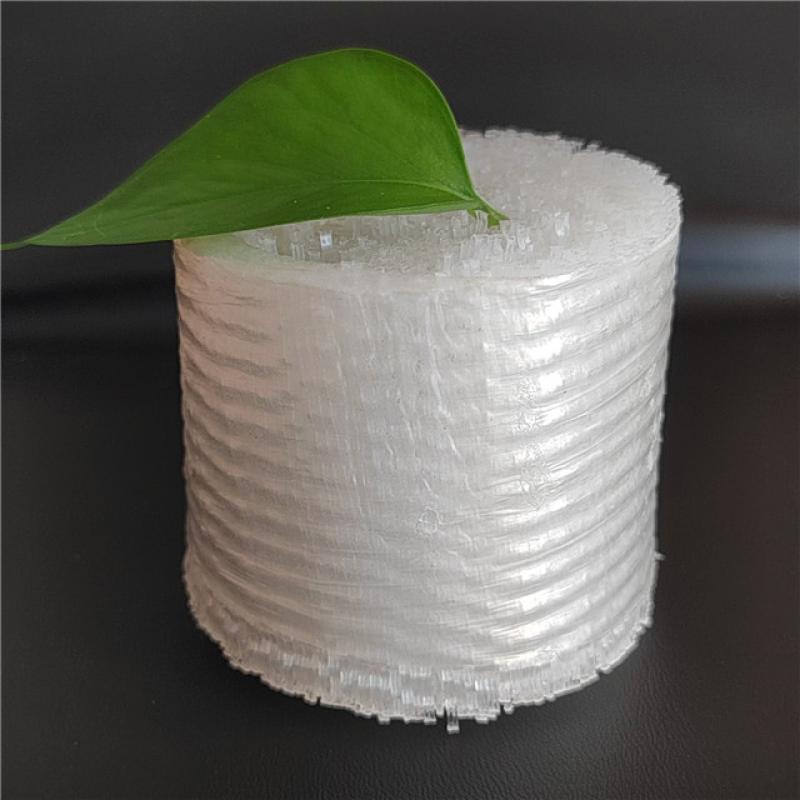

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Связаться сейчас

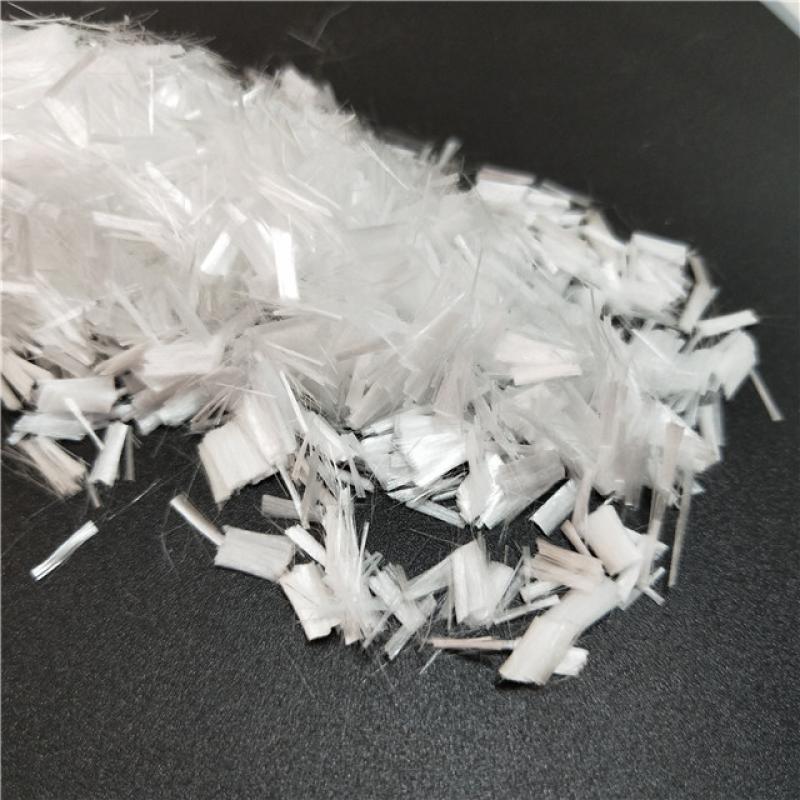

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Связаться сейчас

Synthetic PP Staple Fiber Polypropylene PP Macro Fiber for Concrete EngineeringProduct Details Concrete pp fiber is made via a hundred% virgin polypropylene,adopting unique manufacturing manner to make excessive strength bundle monofilament fiber. While the fiber is put into the concrete,concrete (or mortar) can effectively manipulate concrete (or mortar) Micro-cracks that's resulting from plastic shrinkage, temperature modifications and different elements, to save you and Inhi

Связаться сейчас

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Связаться сейчас

Bundle Polypropylene Twisted Fibers For ConcreteBundle twisted polypropylene fiber is composed of multiple fiber bundles.It is processed through special parallel wire drawing and twisting forming processed and surface treatment.Polypropylene twisted fibers have high strength,it can withstand greater forces.This structure makes the fibers not easy to break when subjected to external forces.Compared with steel fiber,it has advantages of acid,alkali resistant,excellent tensile,easy dispersing,convenience for construction and no damage to the mixing equipment.Polypropylene twisted Fiber technical

Связаться сейчас

HDPE Geomembrane Fish Farm Pond liner is produced from high density polyethylene resin by film-blowing process, adding carbon black, antioxidant, anti-aging and UV-resistance component. Now it is the most widely used products for swimming pools, artificial lake, artifical river and water containment applications. After testing, the quality meets the ASTM standard GM GRI 13 completely.We confirm : 100% virgin HDPE + 2~3% carbon black + antioxidant, anti-aging and UV resistance component.We supply : Advanced equipment + 24 hours production + test each roll+

Связаться сейчас

Benefits Of Polypropylene Micro Fiber Reinforced Concrete Polypropylene (PP) is a semi-crystalline thermoplastic. Using fiber-grade polypropylene as the raw material, it is a high-strength bundle-shaped mono-filament organic fiber formed by a special process. Its inherent strong acid resistance, strong alkali resistance, weak thermal conductivity, and extremely stable chemical properties. Polypropylene Fiber is also called Engineered Fiber,Concrete Fibers,is made by 100% new polypropylene.It

Связаться сейчас

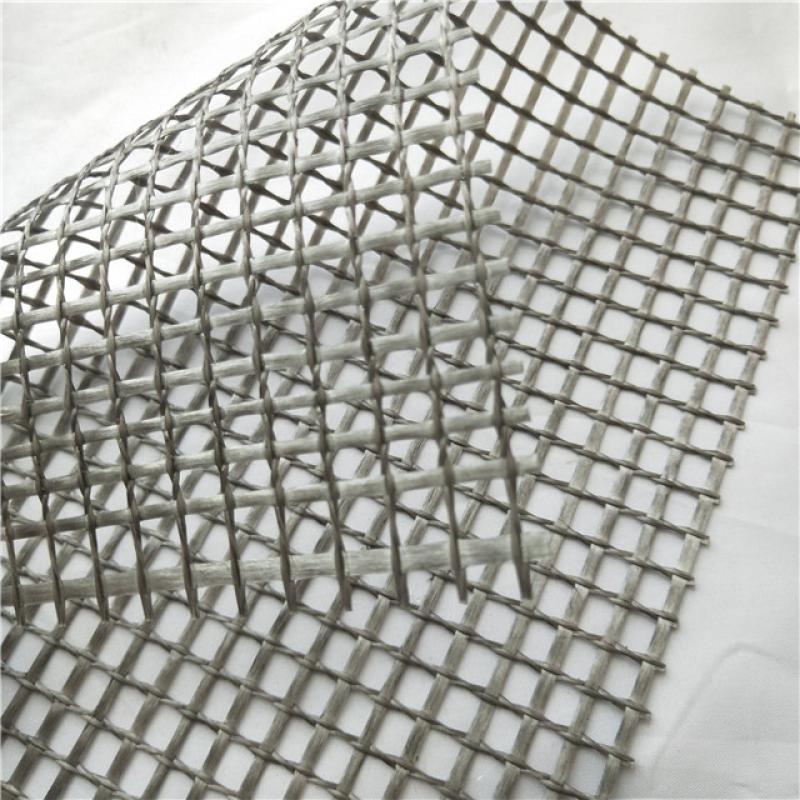

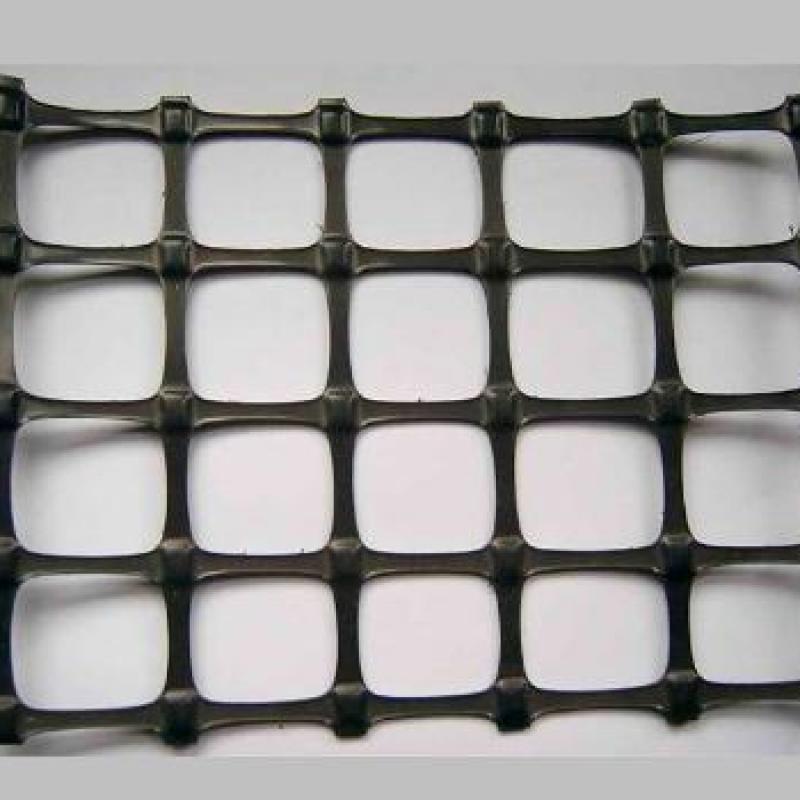

Hot Sale Reinforced Fiberglass Alkali Resistant Mesh Netting Fabric For ConcreteFiberglass mesh is fiberglass leno cloth because the substrate, the anti-emulsion polymer coating after immersion, which has appropriate Alkali resistance, flexibility and robust tensile energy, it is able to be extensively utilized in exterior insulation finishing system (eifs), roofing System, marble,etc.1.Factory supply2.Quick delivery3.Perfect serviceFiberglass mesh is mainly alkali-resistant fiberglass fabri

Связаться сейчас

Factory Direct 100% Polypropylene PP Micro FiberShandong Luke is a professional company that mainly produces and sells concrete crack-resistant fibers and anti-seepage series of geotechnical materials.PP micro fiber is one of the products.Polypropylene micro fiber is a white high-strength bundled monofilament fiber.It is made of 100% polypropylene as its raw material.It is widely used in various construction fields.The characteristics of polypropylene fiber are as follows:Polypropylene micro fiber(PP micro fiber) has good dispersion and strong grip.Polypropylene micro fiber(PP monofilame

Связаться сейчас

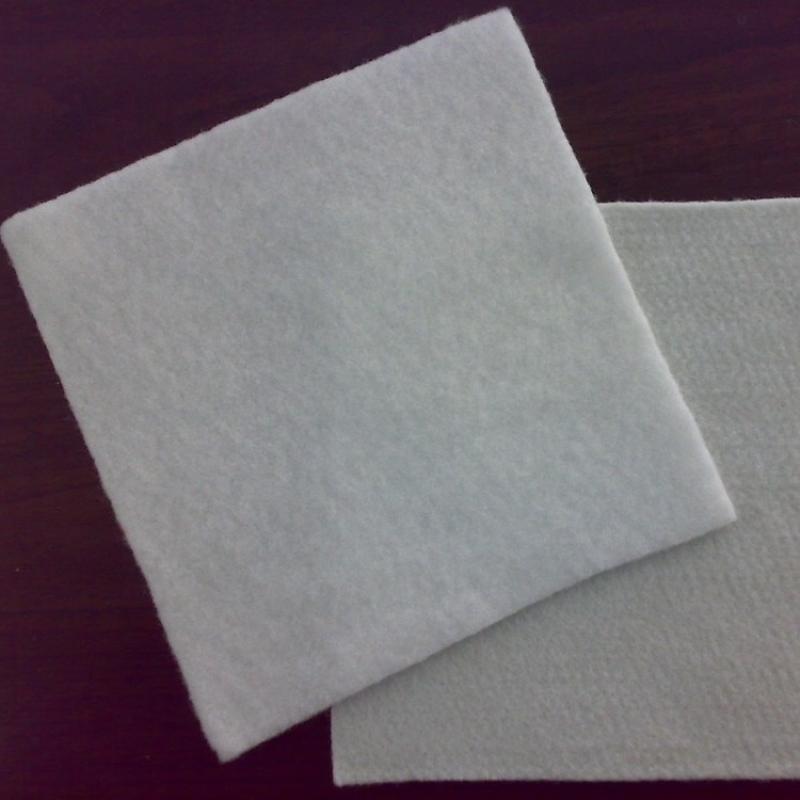

Filament Polyester Non-woven GeotextilePolyester filament geotextile is also called filament non-woven geotextile/polyester non-woven geotextile.The filament non woven geotextile is produced from polyester long fiber forming into net and consolidation with three dimension structure.It is kind of new material in geotechnical and engineering project.Expect for its good mechanical properties of tensile strength and puncture resistance,it also had good drainage ability,acid and alkail resistance and antiaging.Main function of filament polyester geotextile:1、Filament polyester geotextile can play a

Связаться сейчас