Product DetailsHdpe geocell is made from a brand new form of high electricity geosynthetic, that's popular with both domestic and abroad, in accordance with gb/t 19274-2003 implementation of the requirements, which welding the bolstered hdpe sheets via way of the excessive-strength ultrasonic and forming to be a structure of three-dimensional reticular formation this is without problem folding.And handy for transportation.Even as it is be in introduction,the hdpe geocell can be pull right into a network and launched right into a 3-dimensional honeycomb grid.Because it filled in sol,macadam

Связаться сейчас

Product Details The Woven geotextile is produced by virgin polypropylene fiber ,is made of at least two rows of parallel yarns(or tape yarn),using different weaving machines and technologies to weave the warps and wefts into textile shape with various thickness and compactness according to usage ranges. In general,woven geotextile is with relatively light in weight,strong tensile strength,smaller elongation as well as brilliant stability. Our Polypropylene woven geotextile is relatively light in weight, strong tensile strength, smaller elongation as well as brilliant stability.

Связаться сейчас

Application Of Polypropylene Fiber Reinforced Concrete Polypropylene fiber is also known as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. Polypropylene (PP) is a semi-crystalline thermoplastic.

Связаться сейчас

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Связаться сейчас

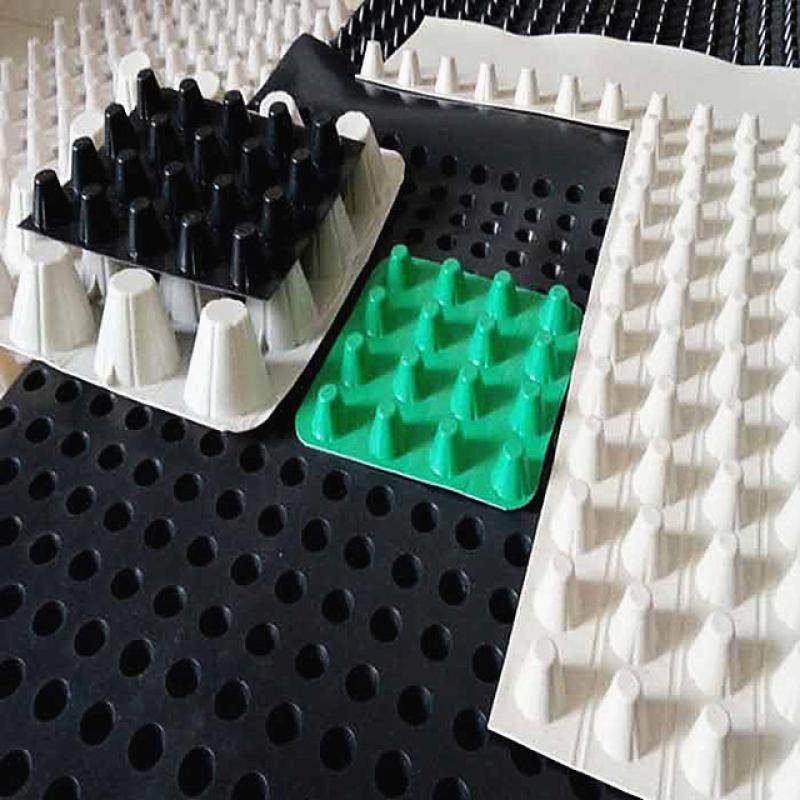

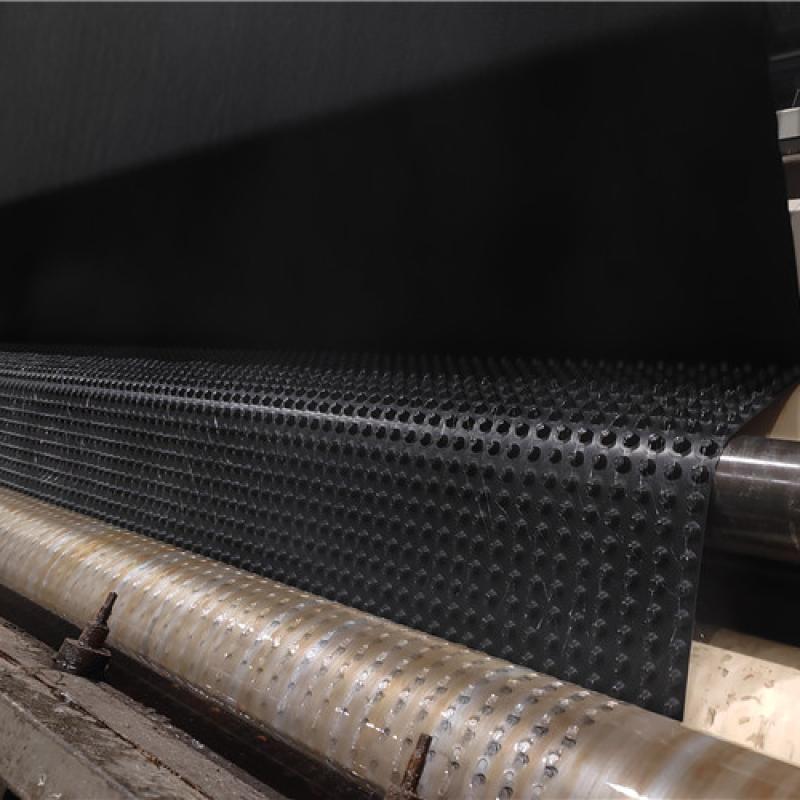

Product DetailsComposite drainage net is made from geonet bonding two layers of geotextile which combines the properties of geotextile filtration and geonet drainage and protection,providing complete“inverted filter drainage to protect”effect.Drainage nets core is extruded by high density polyethylene raw materials adding carbon black and ultraviolet and antioxidant stabilizer.The interlaced net forms into a drainage channel which has good vertical drainage properties.ParameterTest PropertiesUnitDN750DN1000DN1300DN1600Unit weightG/M²750100013001600ThicknessMM5677.6Hydraulic ConductivityM/SK*10

Связаться сейчас

Product DetailsComposite drainage net is made from geonet bonding layers of geotextile which combines the homes of geotextile filtration and geonet drainage and safety,providing entire“inverted clear out drainage to shield”effect.drainage nets center is extruded by way of excessive density polyethylene uncooked materials adding carbon black and ultraviolet and antioxidant stabilizer.the interlaced net office work right into a drainage channel which has fantastic vertical drainage residences.ParameterTest PropertiesUnitDN750DN1000DN1300DN1600Unit weightG/M²750100013001600ThicknessMM5677.6

Связаться сейчас

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Связаться сейчас

Product Details As a new type concrete-strengthening fiber, it becomes a new popular subject in the field of fiber concrete application after glass fiber and steel fiber. Reinforced Functions to Concrete: compared with steel fiber, full-dispersed polypropylene fiber has advantages in its thinness, large amount, non-water absorbency, strong acid & alkali resistance and similar elastic modulus with that of concrete.ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)6,12,18,24,36mm......Elastic Modulus(Mpa)>3500ShapeBeam-like NetEquivalent Dia(μm)

Связаться сейчас

Product DescriptionGeotextile Products is made from 100% virgin staple polypropylene fibers that are tangled and interlocked with each other by needle-punching processes. Non woven polypropylene fabric is the kind of Geotextile Products which is robust, durable, permeable and resist to deformation. Non woven polypropylene geotextile is widely used to increase ground support and soil stabilization in a given location, it has the characteristics of high tensile strength, high elongation rate, excellent UV stabilization, excellent filtration and good abrasion resistance, etc.

Связаться сейчас

High Quality Waterproof HDPE GeomembranesShandong Luke Composite Materials Co., Ltd. is a professional company specializing in the production and sales of geomaterials. The company mainly produces and operates geotextile, geomembrane, drainage plate, geoglage, grid room, three-dimensional geoglage mat, geoglage mat, composite drainage net, grass grid, etc.Shandnong Luke Composite Co;LTd.

Связаться сейчас