Plastic Geogrids-manufacture,factory,supplier from China

(Total 10 Products for Plastic Geogrids)

Product DetailsSteel plastic geogrid is characterized via using high corrosion resistance and fantastic placed on resistance.

Связаться сейчас

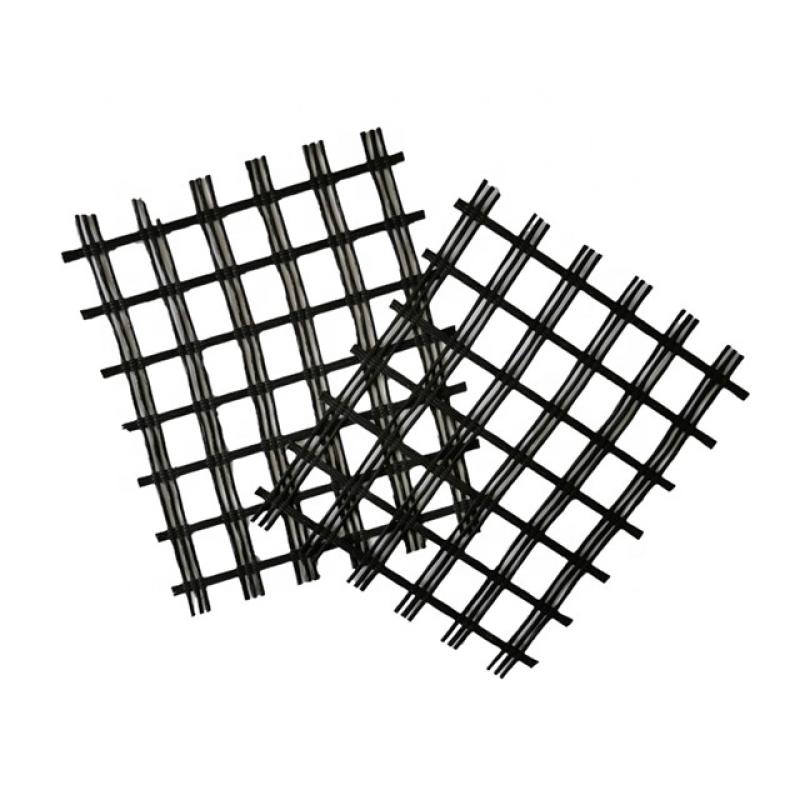

Product DetailsFiberglass geogrid is made of excellent reinforcement type non-alkali glass fiber yarn which is weaved into base material by using foreign advanced warp knitting directional structure. Fiberglass geogrid can make full use of yarn textile strength to improve its chemical performance, high tension resistance, tearing resistance and creep resistance. Fiberglass geogrid system is widely used to reinforce road surface, prevent highway harm such as crack and rut from occurring, solve the problem that asphalt road surface is difficult to reinforce.ParameterItem

Связаться сейчас

Product DetailsFiberglass geogrid reinforcement can effectively enhances the bearing capability of basis and forestalls the soil from lateral displacement because of its high friction coefficient and the bearing ability.

Связаться сейчас

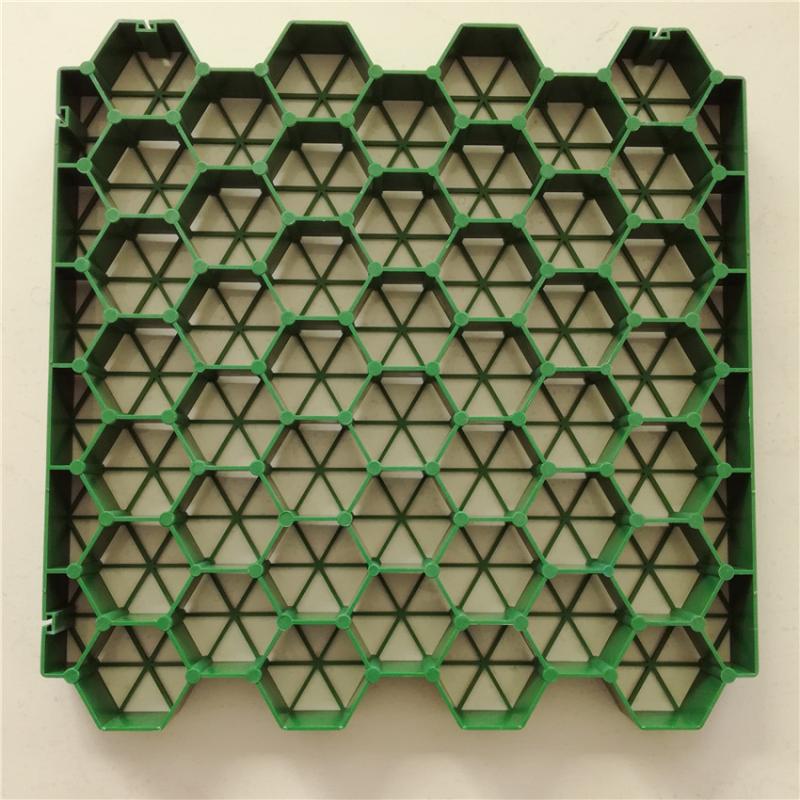

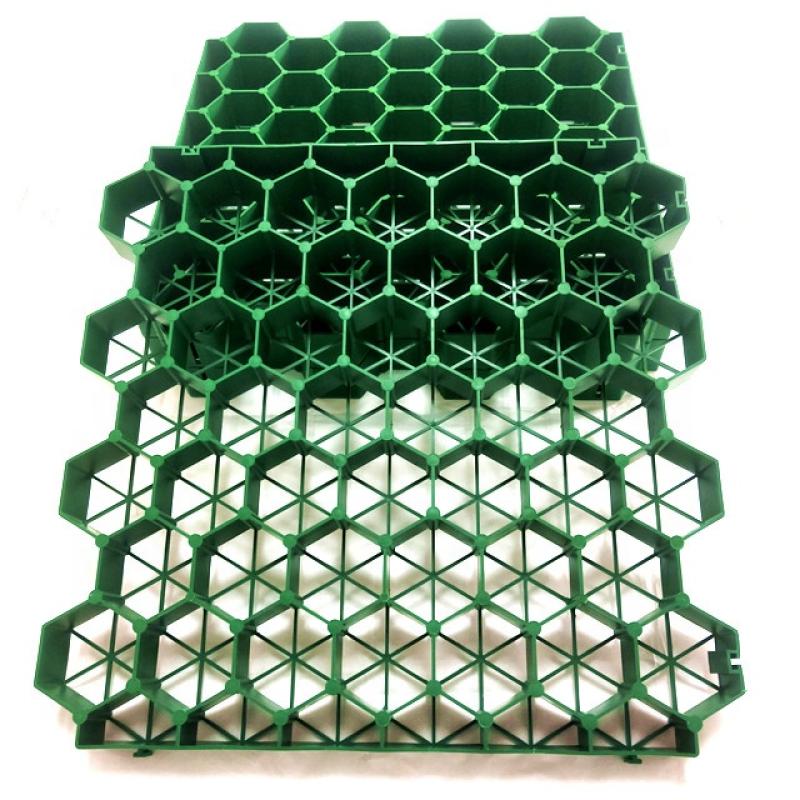

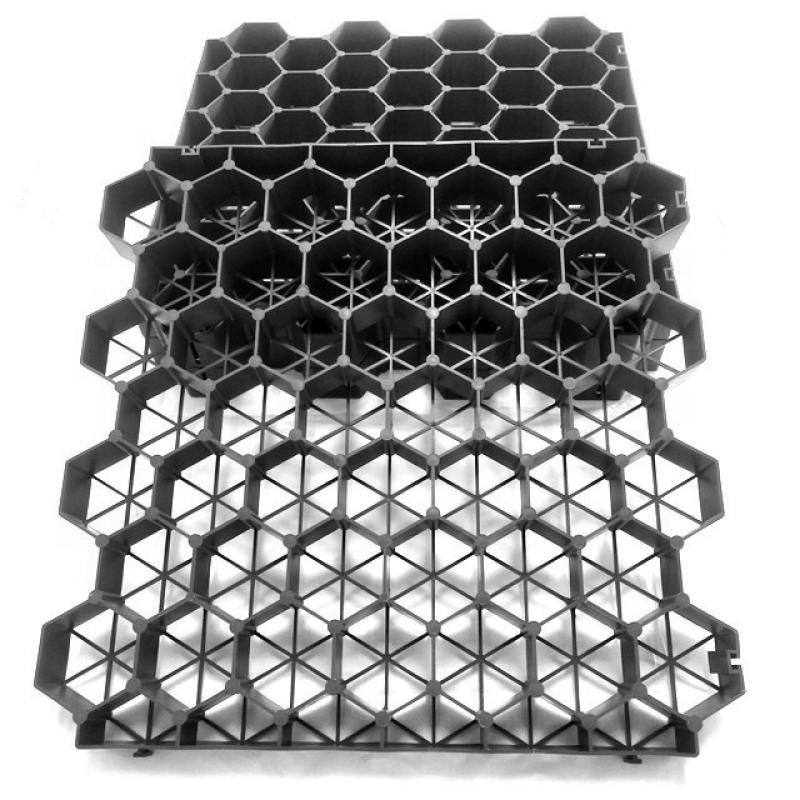

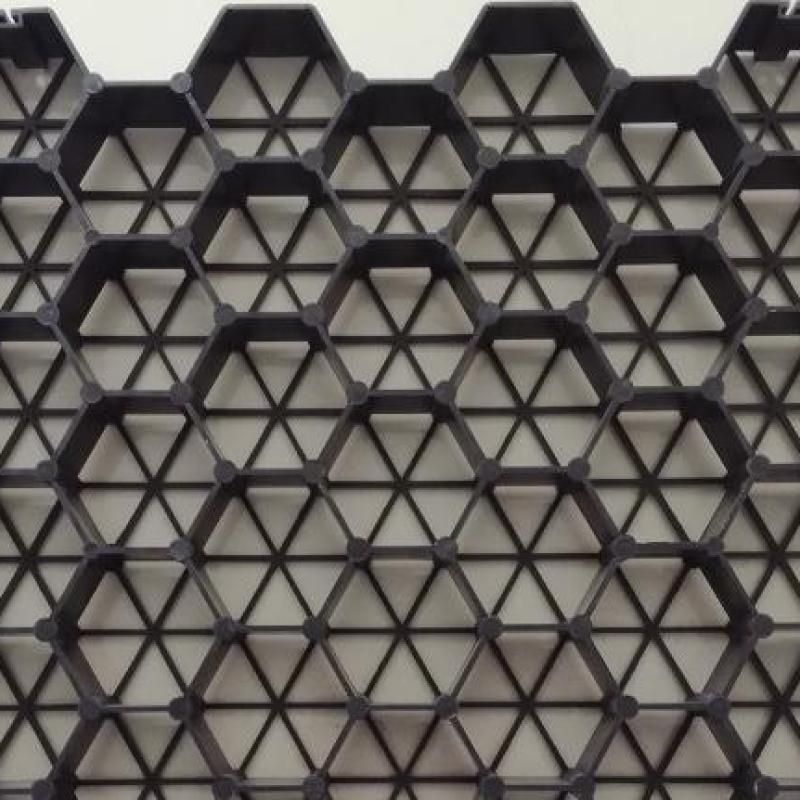

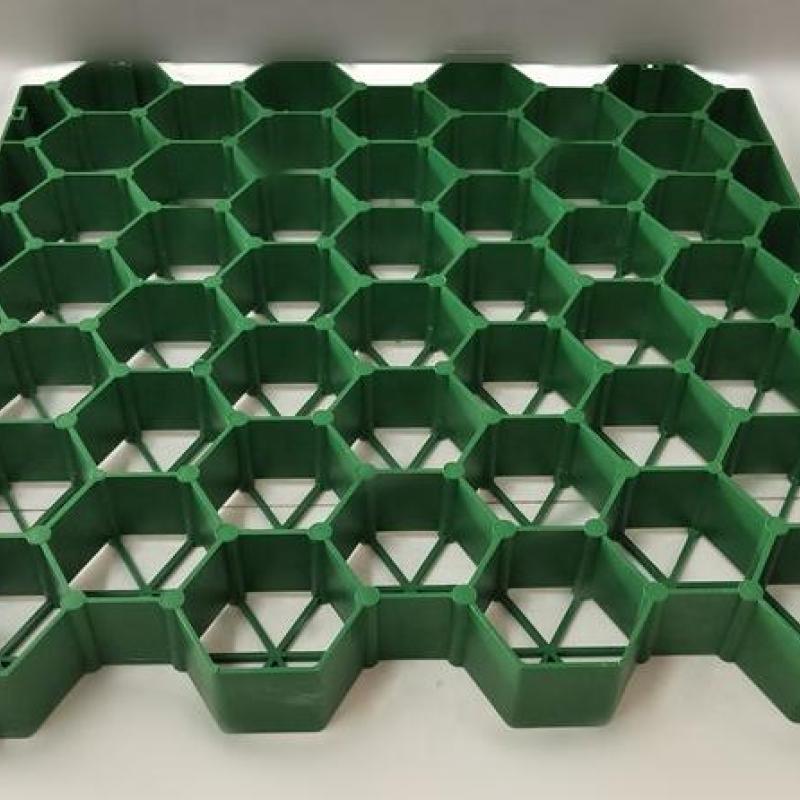

Plastic Grass Paving Grid 50mm for Lawn Parking Lot DrivewayPlastic grass paving grid is made from PP or HDPE (high-molecular polyethylene) with fiber and age resistor, using high pressure to inject plastic to form bee nest-like shaped shell, with stereo space and support level. It’s widely used in parking lot, fire exit, fire climbing surface, pavement etc.

Связаться сейчас

GRASS PAVERs are environmentally friendly. They are made from recycled plastic and allow the drainage of storm water back into the underground soil rather than into storm drains. This helps keep your property hydrated and reduces runoff into local sewer systems. 1. Pervious Load Bearing Surface 2. Stormwater Pollution Filtration and Treatment 3. Airborne Dust Capture and Retention 4. Heat Energy Reflection Reduction, “Cool” Surface 5. Tree Growth within Parking Areas 6. 92% Void Space for Healthy Root Development 7.100% Real Grass Coverage 8.

Связаться сейчас

Product DetailsMetal plastic geogrid is characterised by using high corrosion resistance and incredible put on resistance.

Связаться сейчас

Product DetailsMetal plastic geogrid is characterised by using high corrosion resistance and incredible put on resistance.

Связаться сейчас

Product DetailsMetallic plastic geogrid reinforcement can correctly complements the bearing ability of foundation and stops the soil from lateral displacement because of its excessive friction coefficient and the bearing capability.

Связаться сейчас

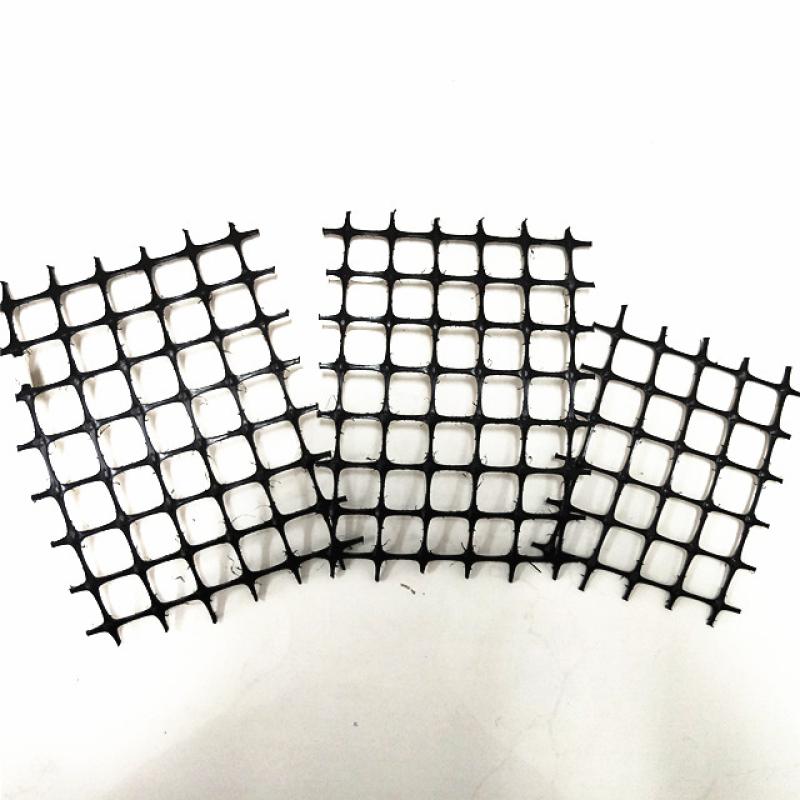

Product DetailsSteel Plastic Geogrid is characterized by high corrosion resistance and excellent wear resistance. It is made of high strength steel coated with virgin polyethylene or high density polyethylene by special ultrasonic welding technology. Steel plastic geogrid reinforcement is weld into longitudinal and latitudinal staggered intervals in the same planner, different wire mesh diameter and root number can be fabricated according to project reinforcement force requirement.

Связаться сейчас

GRASS PAVERs are environmentally friendly. They are made from recycled plastic and allow the drainage of storm water back into the underground soil rather than into storm drains. This helps keep your property hydrated and reduces runoff into local sewer systems. 1. Pervious Load Bearing Surface 2. Stormwater Pollution Filtration and Treatment 3. Airborne Dust Capture and Retention 4. Heat Energy Reflection Reduction, “Cool” Surface 5. Tree Growth within Parking Areas 6. 92% Void Space for Healthy Root Development 7.100% Real Grass Coverage 8.

Связаться сейчас

Relate News

Plastic geogrid includes biaxial geogrid and uniaxial geogrid in line with its shape.Biaxial geogrid is product of polyethylene or excessive density polyethylene as the principle uncooked material through the approaches of heat-soften extrusion, vertical and horizontal stretching to form a excessive power reinforced rectangular mesh shape.Uniaxial geogrid is product of excessive molecular polymer after extruded and laminated and punched into normal mesh earlier than longitudinal stretching.this device makes excessive molecule in direct line u . s .

In the winter season, because of its climate, environment and other factors, there will inevitably be some difficulties during construction. For example, when constructing geogrids, we have to work hard to face many problems. . In areas with repeated freezing and thawing, when the day and night average temperature is below -3°C for more than 10 consecutive days, subgrade construction is called subgrade winter construction. When the day and night average temperature rises above -3°C, but the frozen soil is not completely melted, Construction is also carried out in winter. 1.

The Advantages Of Plastic Grass Grid Over Grass Planting Brick The wheel pressure of the car is 100 tons /㎡, parking on the general grass will make the floor sink, at the same time, the car will roll the grass roots, in order to solve this problem, generally adopt the following two ways, one is to lay grass bricks, the other is to lay plastic grass.

Uniaxial tensile geogrid is a kind of high strength geosynthetics. It is widely used in dams, tunnels, wharfs, highways, railways, buildings and other fields.1. The geogrid enhances the subgrade, which can effectively distribute the diffusion load, improve the stability and bearing capacity of the subgrade, and extend the service life;2. The geogrid can bear greater alternating load;3. Geogrid shall prevent subgrade deformation and cracking caused by loss of subgrade materials;4.

Plastic geogrid consists of biaxial geogrid and uniaxial geogrid in keeping with its structure.Biaxial geogrid is manufactured from polyethylene or immoderate density polyethylene as the principle raw fabric through the tactics of warm-soften extrusion, vertical and horizontal stretching to shape a excessive energy reinforced square mesh form.Uniaxial geogrid is made from high molecular polymer after extruded and laminated and punched into everyday mesh before longitudinal stretching.this machine makes immoderate molecule in direct line united states in square oval net shape with uniform distr

Concrete fibres are high-performance fibres specifically designed for use in concrete/mortar to effectively control micro-cracks caused by plastic shrinkage, dry shrinkage and temperature changes in concrete/mortar, prevent the formation and development of primary cracks in concrete, greatly improve the anti-cracking and anti-permeability properties of concrete/mortar, increase the toughness of concrete and thus improve the service life of concrete.

Concrete fibres, i.e. concrete companion fibres, are commonly used as a raw material for polypropylene resin and are specifically designed to prevent or reduce the initial plastic cracking in cement concrete, acting as a "secondary reinforcement" for cement concrete.Concrete fibres are made by blending, spinning and stretching modified masterbatch into polypropylene chips.

2024. April, we exported 1x40HQ Polypropylene Macro Concrete Fibers to Europe Market.The fiber is Polypropylene Twist Macro Fiber for concrete, grey color, high strength, suitable for concrete.We suggest 3kgs at least per m3 concrete. The packing is 1kg/plastic bag, 10kgs/pp woven bag, pack by pallets.

Concrete PP fiber is a polypropylene as the main raw material, adopting unique manufacturing process to make high strength bundle mono-filament fiber.Join concrete (or mortar) can effectively control concrete (or mortar) micro-cracks which is caused by plastic shrinkage,temperature changes and other factors, to prevent and inhibit the formation and development of cracks, greatly improved crack resistance of concrete, impact resistance and seismic capacity.Polypropylene Fibers have many advantages in concrete construction:1. Easy to be dispersed in mortar or concrete and no agglomeration,

Construction site: it is required to be compacted, leveled, horizontal, and the sharp protrusions shall be removed.Grating laying: on a flat and compacted site, the main stress direction (longitudinal) of the installed and laid grating shall be perpendicular to the axis direction of the embankment, and the laying shall be flat, wrinkle free, and tensioned as far as possible. Fix the grid with dowels and earth rock weights. The main stress direction of the paved grid should be full length without joints.