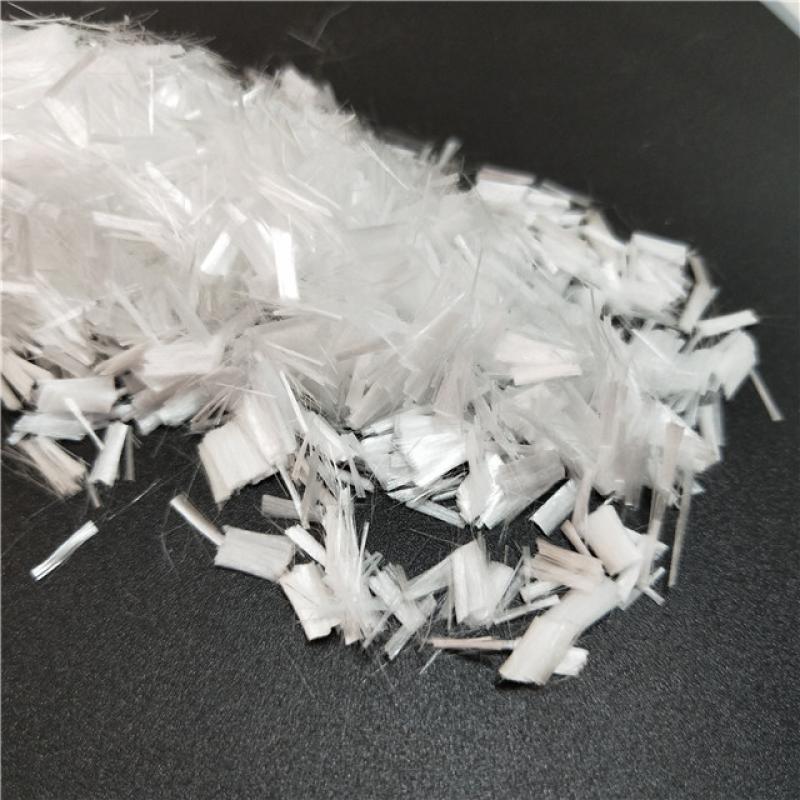

Polypropylene Synthetic Fiber for Shotcrete(wave shape Polypropylene Macro Fiber for Concrete)Polypropylene Synthetic Macrofiber for Concrete, like Shotcrete, replace steel fiber.It has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Связаться сейчас

Hot Sale Reinforced Fiberglass Alkali Resistant Mesh Netting Fabric For Concrete Fiberglass mesh is woven by way of c-glass fiberglass yarn, after which coated via alkali resistant glue.specifically has high assets for acid-resistant and excessive power for concrete reinforcement. Which has properly alkali resistance, flexibility and robust tensile strength, it can be extensively utilized in exterior insulation finishing system (eifs), roofing machine, marble, and many others.1.Factor

Связаться сейчас

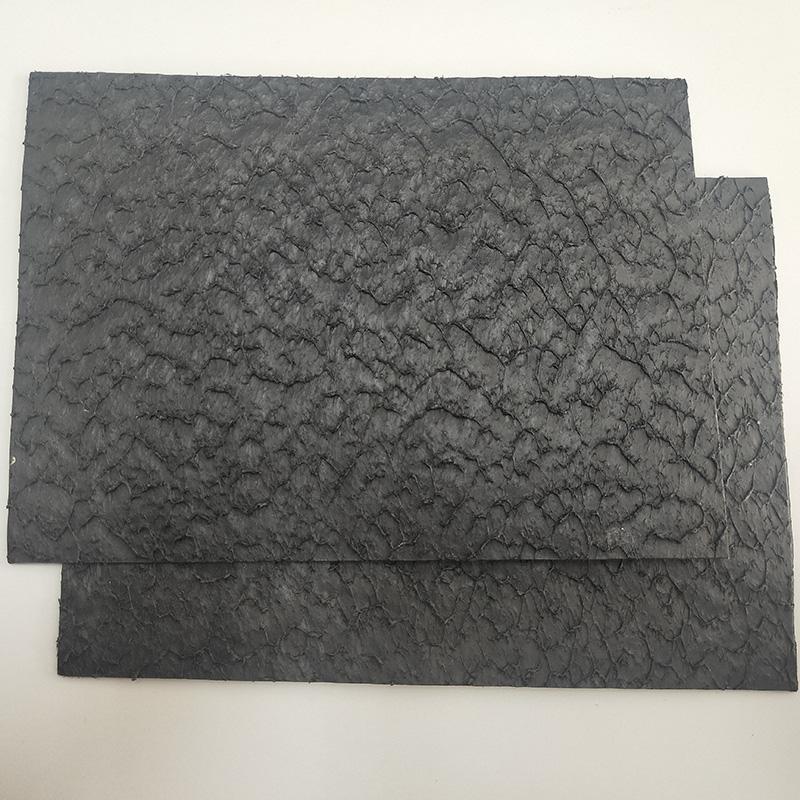

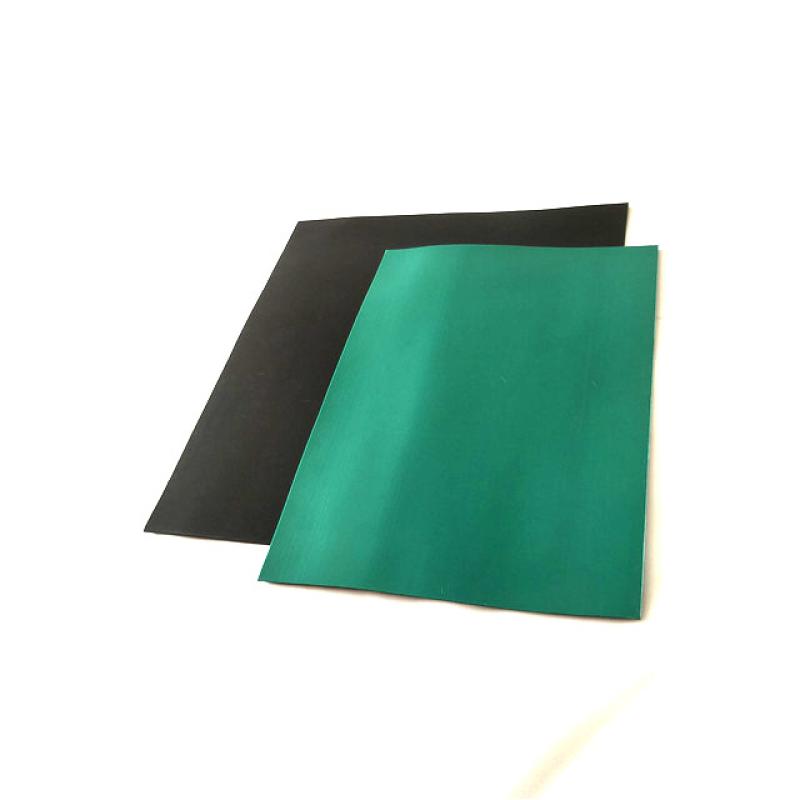

Product DetailsTextured HDPE Geomembrane is designed and fabricated with either single-sided or double-sided textured surface. Textured geomembrane has a rough surface which can highly improve the friction coefficient which fits more suitable for steep slope and vertical engineering design work which maximize the effective volume of geomembrane, they are also processed with smooth edges to allow for high quality thermal fusion welding between adjacent sheets.

Связаться сейчас

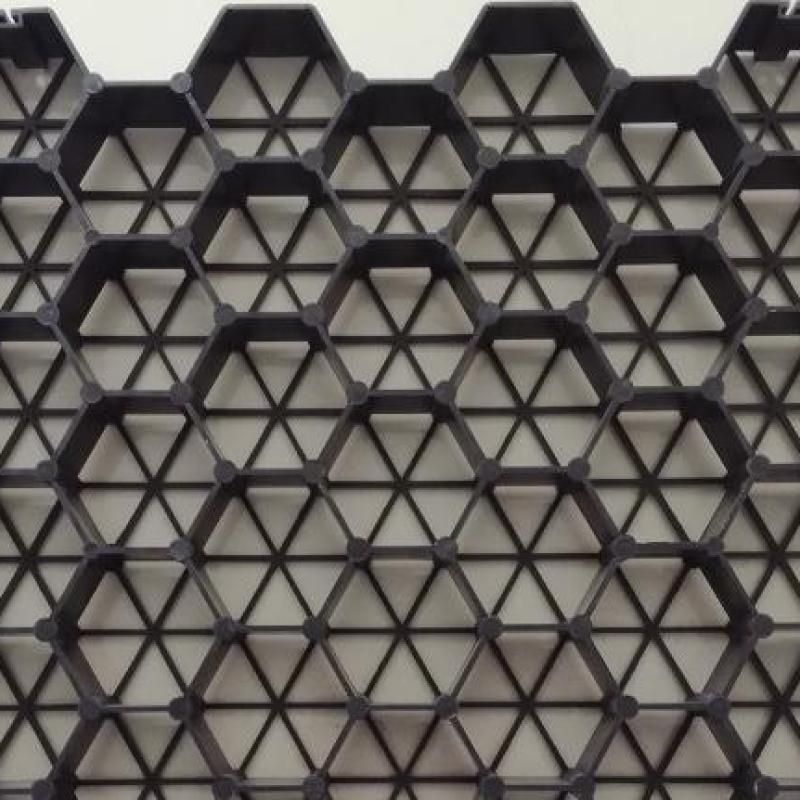

Product DetailsFiberglass geogrid is manufactured from tremendous reinforcement type non-alkali glass fiber yarn that is weaved into base material by way of using overseas advanced warp knitting directional shape.

Связаться сейчас

Concrete PP fiber is a polypropylene as the main raw material, adopting unique manufacturing process to make high strength bundle mono-filament fiber.

Связаться сейчас

Product Details3D Reinforced Geomat Erosion Control Mat For Slope ProtectionThe strengthened geomat is pp mesh mat composited with twine mesh, that's galvanized in case of abrasion control.The shape allows sufficient space for maintaining the soil and grass developing.

Связаться сейчас

Macro-Polypropylene Fiber For ConcreteIn order to overcome the weakness of concrete itself,People introduced macro-polypropylene fiber-reinforced concrete technology.Macro-polypropylene fiber is made of polypropylene through special modification and surface molding process.It has advantage of acid,alkail resistant,So macro-polypropylene fiber be suitable for various environment.Macro-polypropylene fiber not only has Excellent tensile,which can improve the toughness and flexural of concrete,but also has strong crack resistance .It easy dispersing,convenience for construction and no damage to ve

Связаться сейчас

Polypropylene fiber is also called engineering fiber, concrete fiber, anti-crack fiber, synthetic fiber or plastic fiber. We use high tenacity polypropylene resin as the raw material and produce with special technical. Putting the pp fiber into concrete or mortar can control the micro crack caused by the plasticity contraction, air shrinkage and temperature change.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melting Point160-170℃Acid &

Связаться сейчас

Macro Structural Polypropylene FibersMacro Polypropylene fibers ,also known as plastic steel fiber,is refined from polypropylene as the main raw material through a special production process.The surface of polypropylene crude fiber is rough and uneven.It is a new type of reinforced and toughening material.The product not only has the function of steel fiber,but also has the advantages of synthetic fiber.It can replace steel fiber for the crack resistance enhancement of cement concrete.

Связаться сейчас

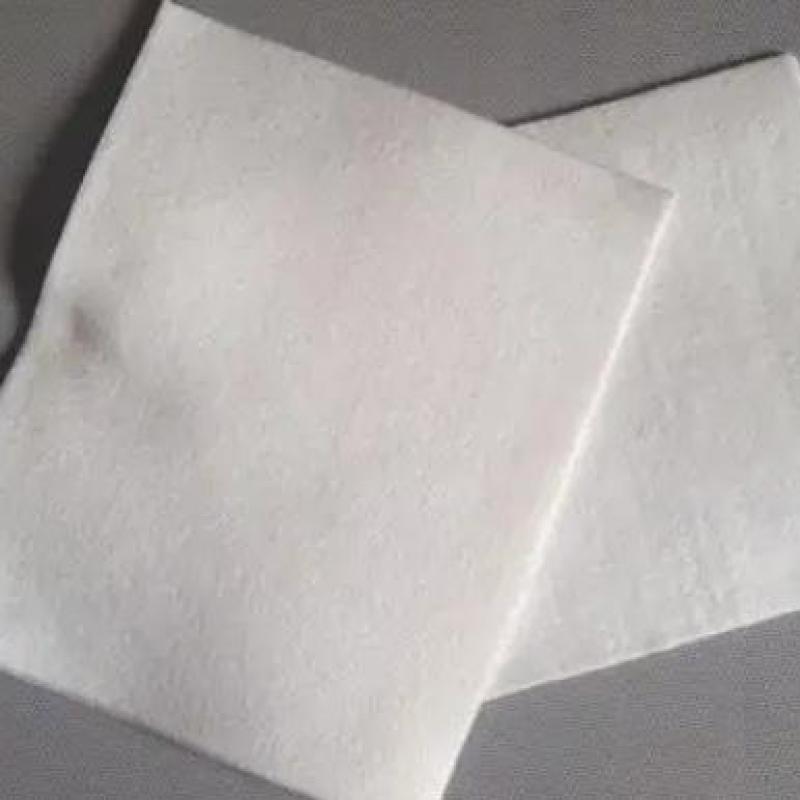

200gsm Polypropylene Polyester Nonwoven GeotextileThe needle punched non woven geotextile is produced from polyester or polypropylene fiber by different equipment and technology to get different thickness.Our commonly used geotextiles are 200g/m2,300g/m2,400g/m2, and custom geotextiles.

Связаться сейчас