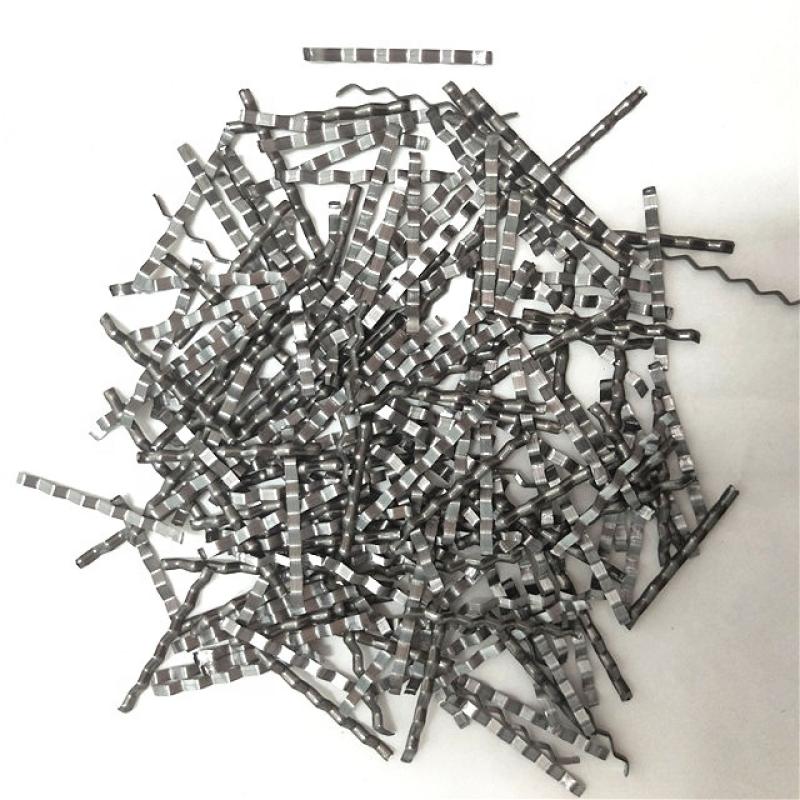

In the concrete mixture, add right amount steel fiber can be mixed into a kind of special jetting as well as casting concrete,namely Carton Steel Fiber reinforced concrete Fibers.Compared with general concrete, Carton steel fiber concrete has great improvement in tensile strength, flexural strength, abrasion resistance, impact resistance, fatigue resistance, toughness,crack resistance and antiknock performance, because large number of very minute steel fiber is evenly dispersed in the concrete and has a large contact area with concrete, therefore, concrete strength is improved i

Связаться сейчас

High Tensile Strength Macro Steel Fibers for Concrete Reinforcement In the concrete mixture, add right amount steel fiber can be mixed into a kind of special jetting as well as casting concrete,namely steel fiber reinforced concrete.

Связаться сейчас

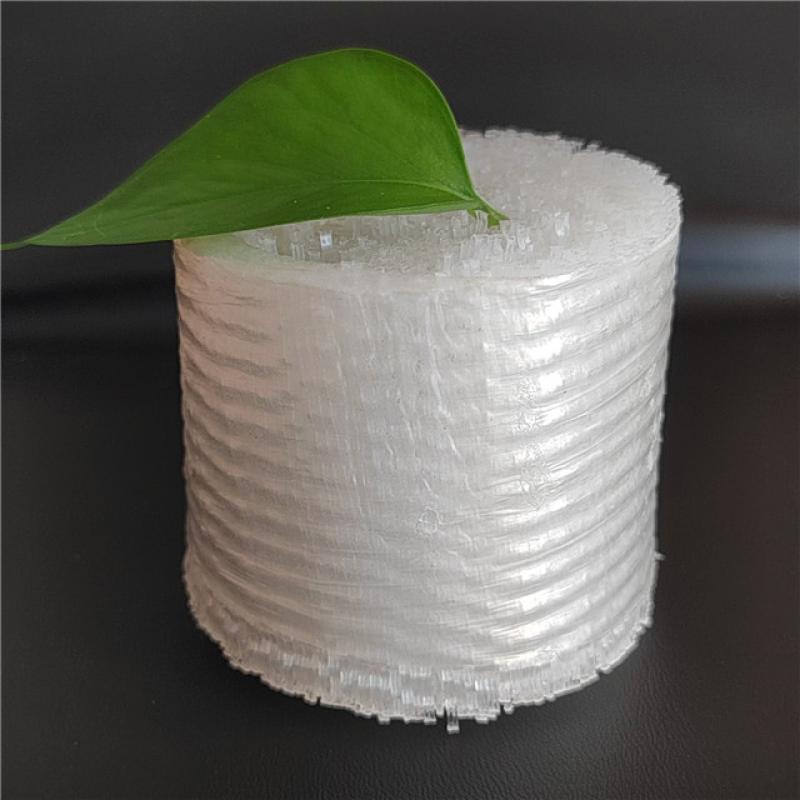

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Связаться сейчас

Product DetailsInside the concrete combination, add proper amount steel fiber may be mixed into a type of special jetting as well as casting concrete, specifically metal fiber bolstered concrete.In comparison with fashionable concrete, metallic fiber concrete has high-quality development in tensile strength, flexural strength, abrasion resistance, effect resistance, fatigue resistance, sturdiness, crack resistance and antiknock overall performance, due to the fact huge quantity of very minute steel fiber is frivolously dispersed within the concrete and has a massive contact place with concrete

Связаться сейчас

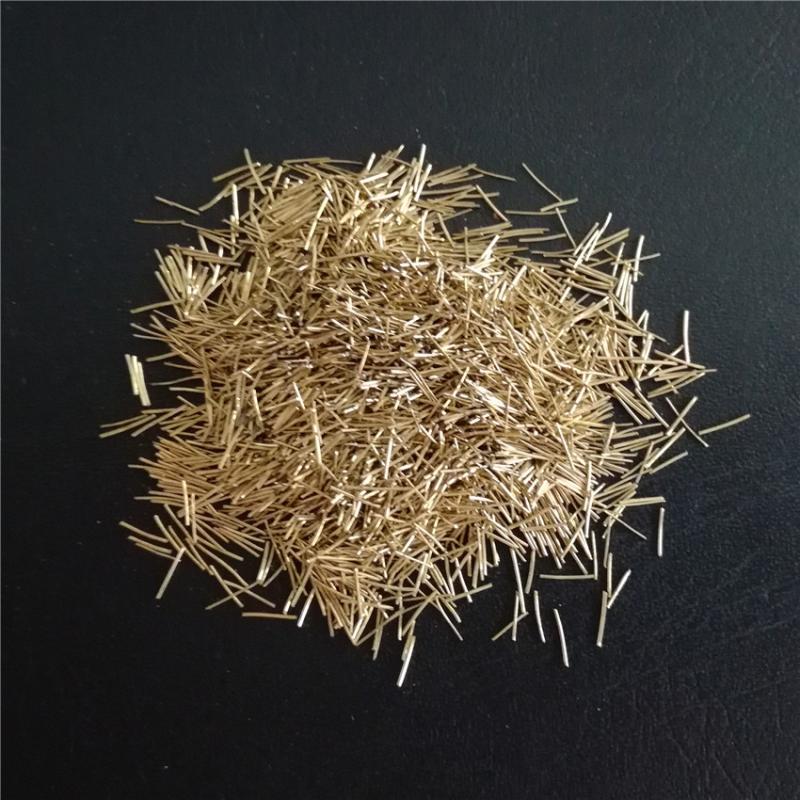

It‘s the special kind of metal fiber with very high of compressive intensity, tensile intensity, crack resistance.It is widely uesd in high-speed rail precast,RPC cover Board,important projects components and exterior painting. It can improve the performances of the conceret,such as anti-tensile, anti-compressive,shear intensity,impermeability,impact resistance,fatigue resistance,and so on. Tensile Strength > 2800MPA0.2 ~0.3mm diameterLength as your requestApplication Its widely used in highway, bridge, tunnel, airport runway, industrial floor, hydraulic project and bas

Связаться сейчас

High Tensile Strength Micro Copper Coated Steel Fibers For Concrete Constructions Copper coated micro metal fiber is one in all most critical substances of rpc ( reactive powder concrete ). RPC has the capabilities of very high strength, high tenacity, very good durability and extent stability. Micro Copper Coated Steel Fiber is a superb and a new type of construction substances. Steel Fiber for Concrete is miles extensively used inside the building of high pace railway, limited-access highway,

Связаться сейчас

Product Details China Supplier Copper Coated Steel Fiber for Concrete Reinforcement Copper Coated Micro Steel Fiber is one of most important materials to be used for construction and concrete. Micro Steel Fiber is widely used in the building of high speed railway, expressway, concrete reinforcement and constructional elements.ParameterMaterialCopper coatedTypeStraightLength(mm)5mm-60mmEquivalent Diameter(mm)0.2-0.3Tensile Strength (Mpa)≥2800L/D Ratio65 FeatureA) Tensile strength is enhancedB)

Связаться сейчас

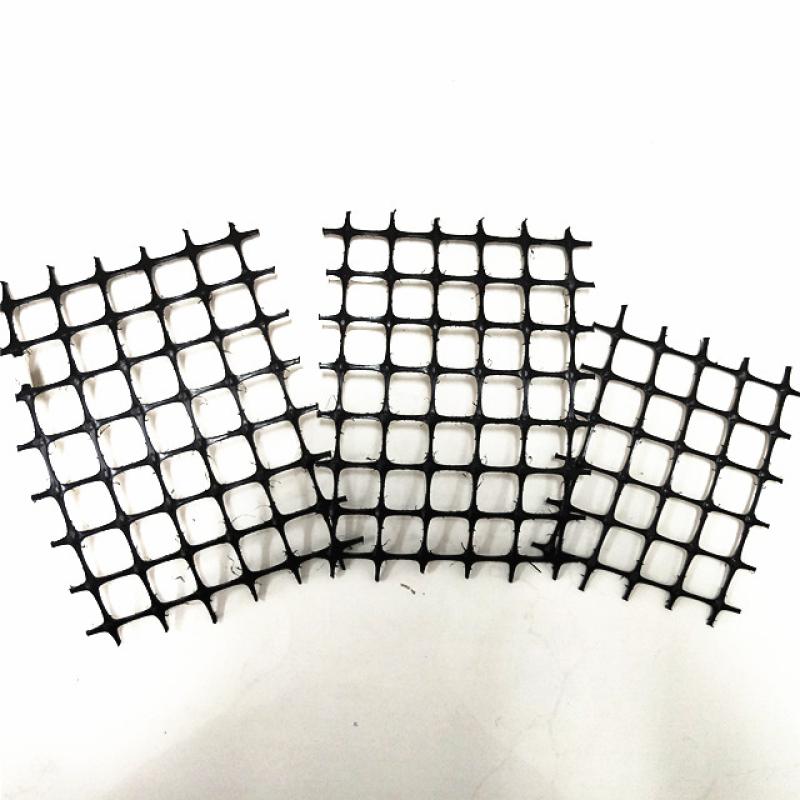

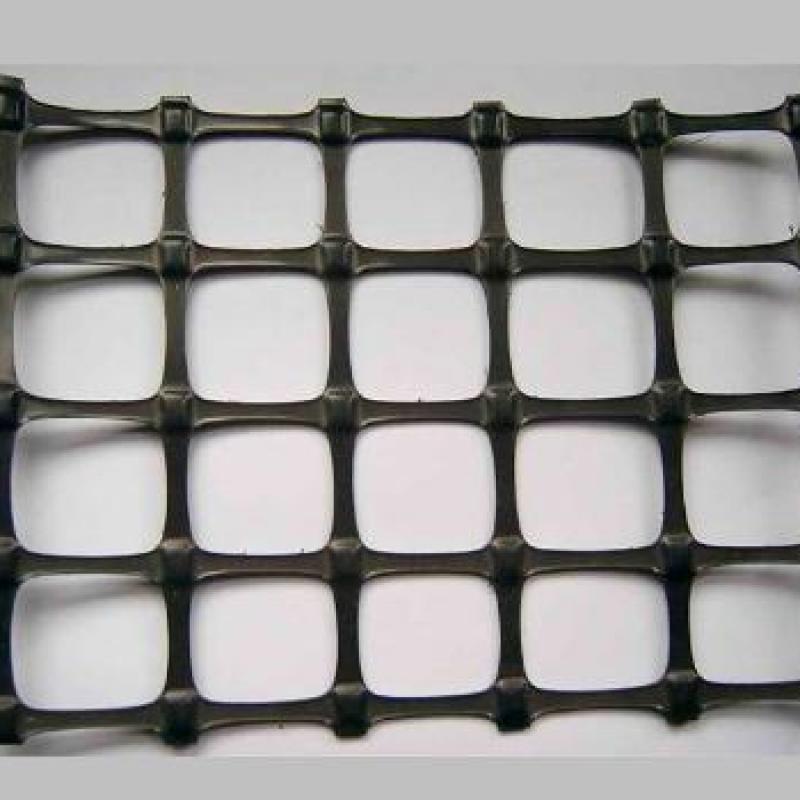

Product DetailsSteel Plastic Geogrid is characterized by high corrosion resistance and excellent wear resistance. It is made of high strength steel coated with virgin polyethylene or high density polyethylene by special ultrasonic welding technology. Steel plastic geogrid reinforcement is weld into longitudinal and latitudinal staggered intervals in the same planner, different wire mesh diameter and root number can be fabricated according to project reinforcement force requirement.

Связаться сейчас

Micro Wire Copper Coated Steel Fiber For RPC Concrete Reinforcement With Free SamplesDiameter is among 0.2 mm to 0.3mm. Tensile Strength is > 2800 mpa. In keeping with the same old of jg/t 3064-1999 metallic fiber concrete, yb/t 151-1999 metallic fiber for concrete and astm a820-90 steel fiber for the fiber concrete.Copper coated micro metal fiber is one in all maximum vital materials of rpc ( reactive powder concrete ). RPC has the capabilities of very high strength, excessive tenacity, excellent sturdiness and extent bala

Связаться сейчас

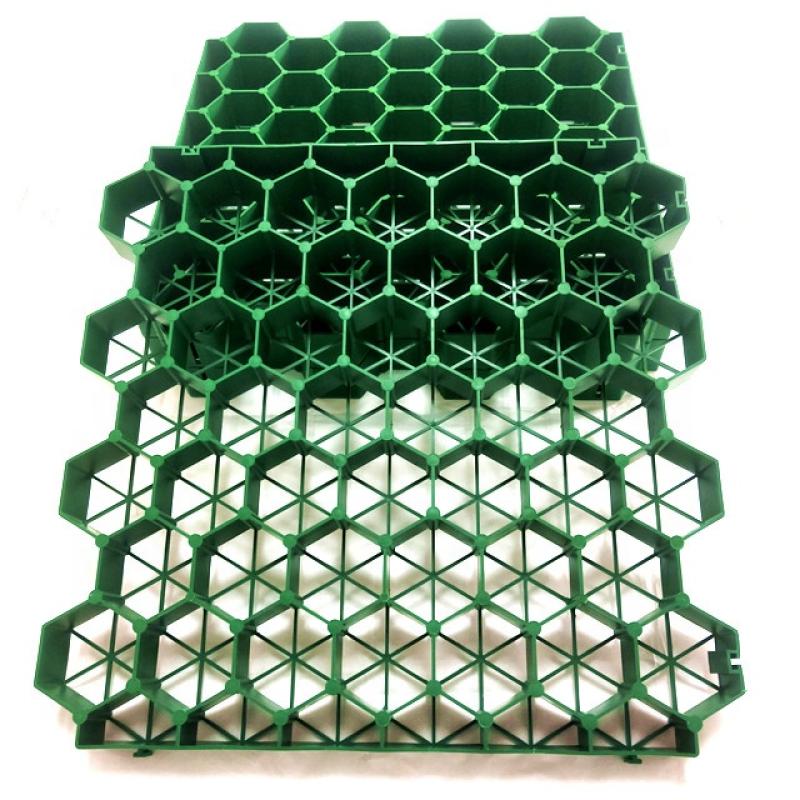

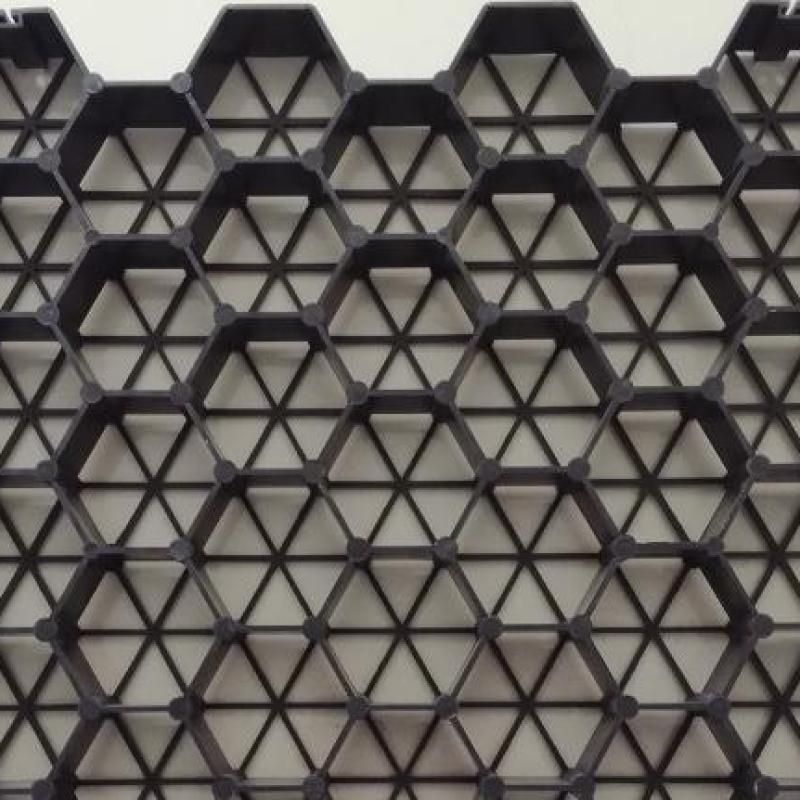

GRASS PAVERs are environmentally friendly. They are made from recycled plastic and allow the drainage of storm water back into the underground soil rather than into storm drains. This helps keep your property hydrated and reduces runoff into local sewer systems. 1. Pervious Load Bearing Surface 2. Stormwater Pollution Filtration and Treatment 3. Airborne Dust Capture and Retention 4. Heat Energy Reflection Reduction, “Cool” Surface 5. Tree Growth within Parking Areas 6. 92% Void Space for Healthy Root Development 7.100% Real Grass Coverage 8.

Связаться сейчас