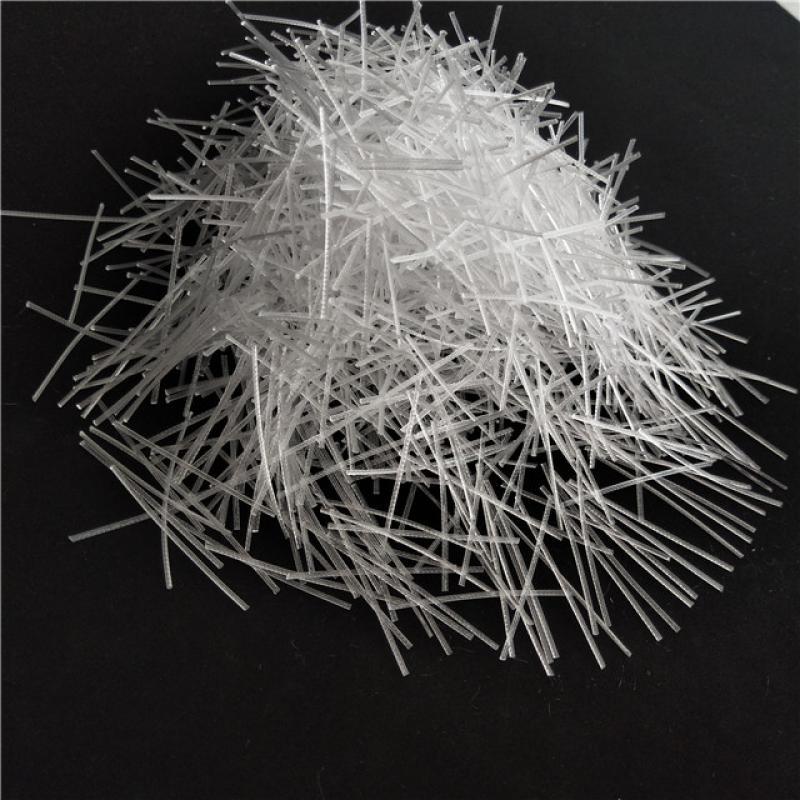

Product Details Grey Black Color PP Twisted Bundle Fiber 38 mm 40 mm 54 mm Polypropylene Fibers for Concrete What is polypropylene fiber? Polypropylene fiber is produced by special technology with 100% polypropylene as its raw material, the products have net-like structure with many fiber monofilaments, with good dispersion,no fascicles, and has a high toughness and strength. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Materi

Связаться сейчас

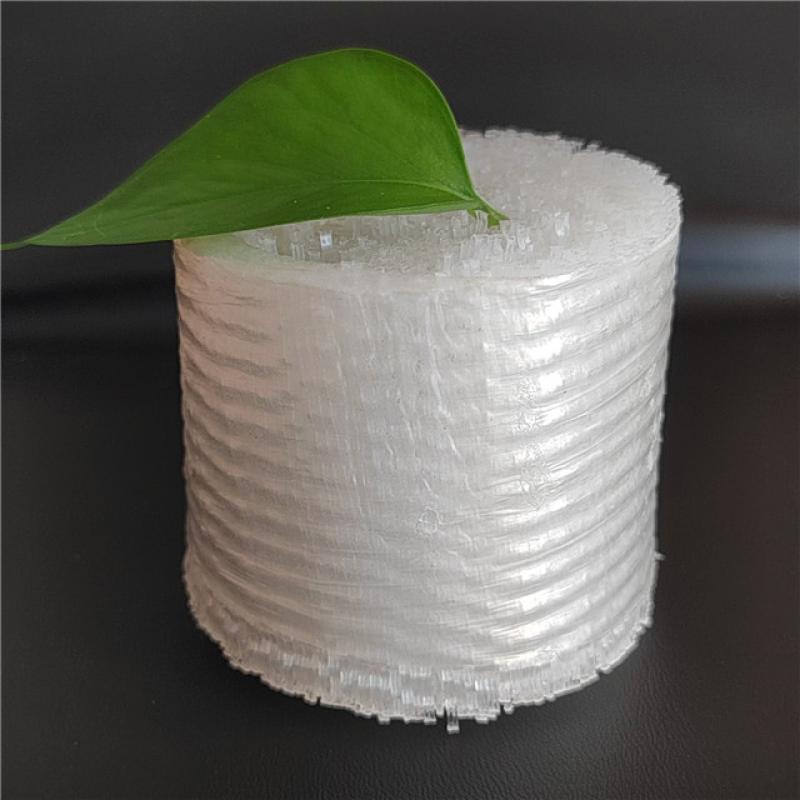

Product Details Twisted package pp fiber is developed for replacement of metallic fiber. With polypropylene as its raw material,it's far produced by way of special drawing twisting and surface remedy. Compared with metallic fiber, it has benefits of acid, alkali resistant, first rate tensile, clean dispersing, comfort for creation and no harm to the combination system. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwi

Связаться сейчас

40 MM High Performance Structural Synthetic Macro FibersProduct Details Concrete pp fiber is made by a hundred% virgin polypropylene,adopting unique production system to make high power bundle monofilament fiber. When the fiber is positioned into the concrete,concrete (or mortar) can efficaciously manipulate concrete (or mortar) Micro-cracks which is caused by plas

Связаться сейчас

China Manufacturer Polypropylene Twist Bundle Fiber for Concrete Reinforcement What is the action principle of polypropylene fiber ? When the pp fiber is put into the concrete, the horizontal structure in fiber monofilament can be destroyed in the course of stirring owing to friction and rubbing, and the fiber monofilament or net- like structure will fully stretch, thus the concrete is reinforced by a great number of polypropylene fibers.ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/Grey

Связаться сейчас

Product Details Twisted Bundle PP Fiber is developed for replacement of steel fiber. With polypropylene as its raw material,it is produced by special drawing twisting and surface treatment. Compared with steel fiber, it has advantages of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction . ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwist or HybridMelting Point160-170 ℃ &n

Связаться сейчас

Product Details Twisted package pp fiber is evolved for replacement of metallic fiber. With polypropylene as its uncooked fabric,it is produced via special drawing twisting and floor remedy. In comparison with metal fiber, it has advantages of acid, alkali resistant, terrific tensile, easy dispersing, convenience for creation and no damage to the integration device. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwist

Связаться сейчас

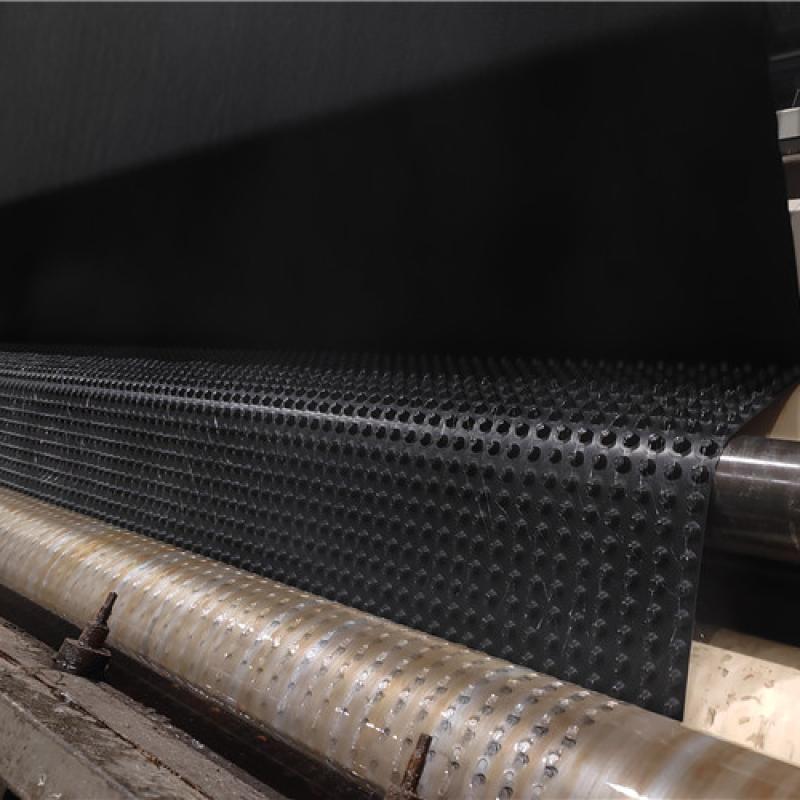

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Связаться сейчас

4 MM -19 MM Polypropylene PP Concrete Reinforced Fibers Polypropylene fiber can improve the adhesion of concrete, reduce cracks of concrete in the early stage. As our experiments, only 0.1% fibers by volume can improve the cracking resistance by 70%, and the impermeability increases by 60%-70%. PP fibers are chemically stable, it has excellent corrosive resistance to expand the self-life of your projects. PP fiber increases impermeability, only 0.9Kg/m3 PP fibers can improve it by 70%. The light-weight (0.91 density) of PP fib

Связаться сейчас

Product DetailsTwist Bundle PP Fiber Bunchy Form Concrete Polypropylene Fibers Twisted package deal pp fiber Bunchy Form Concrete Polypropylene Fibers is superior for replacement of steel fiber. with polypropylene as its raw fabric,it's far produced via special drawing twisting and floor treatment. as compared with steel fiber, it has benefits of acid, alkali resistant, exceptional tensile, easy dispersing, consolation for creation and no harm to device. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000Co

Связаться сейчас

Polypropylene fiber is also known as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber.We use immoderate tenacity polypropylene resin due to the fact the uncooked cloth and produce with particular technical.placing the pp fiber into concrete or mortar can manage the micro crack because of the plasticity contraction, air shrinkage and temperature exchange.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melting Point16

Связаться сейчас