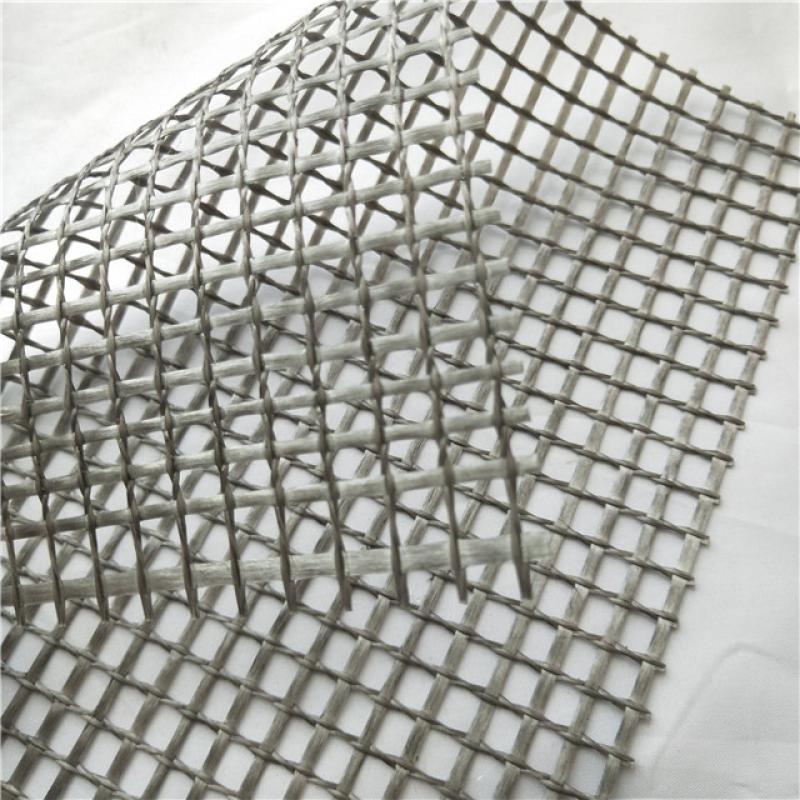

Product DetailsFiberglass geogrid is made of excellent reinforcement type non-alkali glass fiber yarn which is weaved into base material by using foreign advanced warp knitting directional structure. Fiberglass geogrid can make full use of yarn textile strength to improve its chemical performance, high tension resistance, tearing resistance and creep resistance. Fiberglass geogrid system is widely used to reinforce road surface, prevent highway harm such as crack and rut from occurring, solve the problem that asphalt road surface is difficult to reinforce.ParameterItem

Связаться сейчас

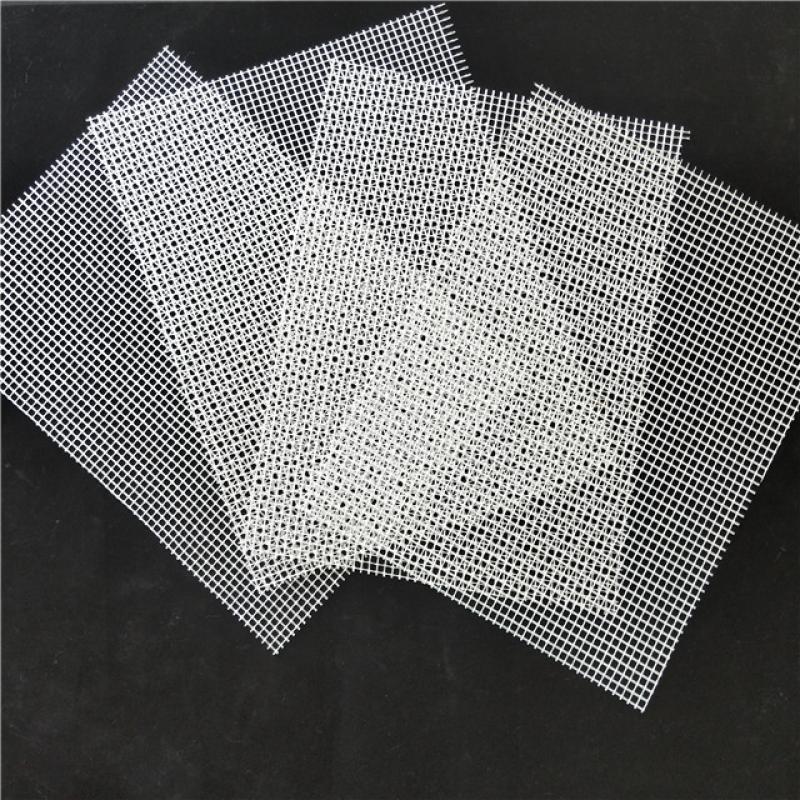

Fiberglass Fabric Cloth MeshFiberglass Fabric Cloth Mesh is fiberglass leno fabric to be the substrate, the anti-emulsion polymer coating after immersion, which has good alkali resistance, flexibility and strong tensile strength, it can be widely used in exterior insulation finishing system (EIFS), roofing system, marble,etc.1.Factory supply2.Quick delivery3.Perfect serviceFiberglass

Связаться сейчас

Hot Sale Reinforced Fiberglass Alkali Resistant Mesh Netting Fabric For ConcreteFiberglass mesh is fiberglass leno cloth because the substrate, the anti-emulsion polymer coating after immersion, which has appropriate Alkali resistance, flexibility and robust tensile energy, it is able to be extensively utilized in exterior insulation finishing system (eifs), roofing System, marble,etc.1.Factory supply2.Quick delivery3.Perfect serviceFiberglass mesh is mainly alkali-resistant fiberglass fabri

Связаться сейчас

Fiberglass Mesh FabricFiberglass Mesh is fiberglass leno fabric as the substrate, the anti-emulsion polymer coating after immersion, which has goodalkali resistance, flexibility and strong tensile strength, it can be widely used in exterior insulation finishing system (EIFS), roofing system, marble,etc.1.Factory supply2.Quick delivery3.Perfect serviceFiberglass mesh is mainly alkali-resistant

Связаться сейчас

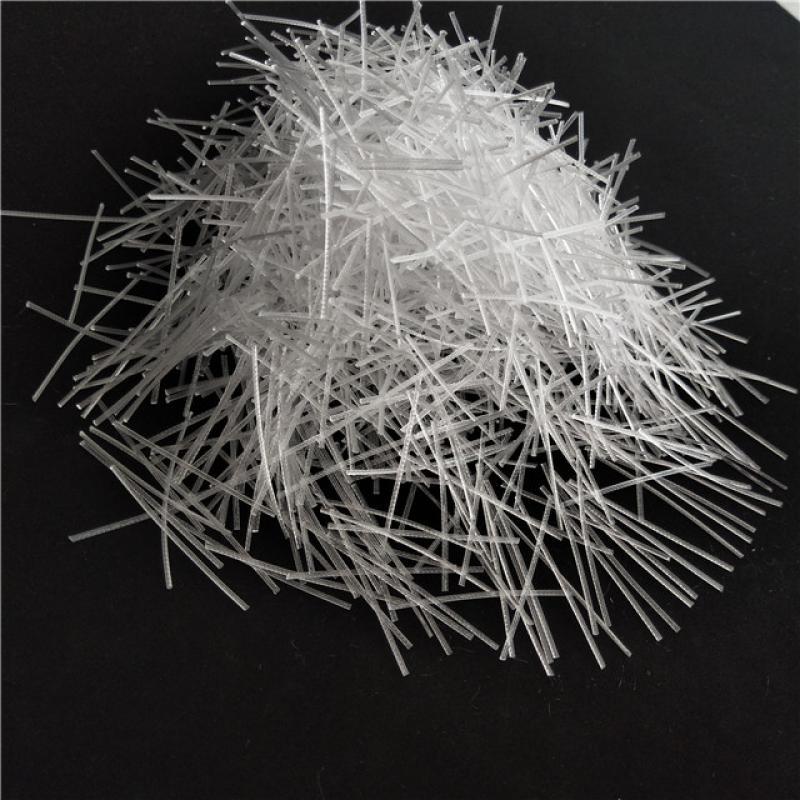

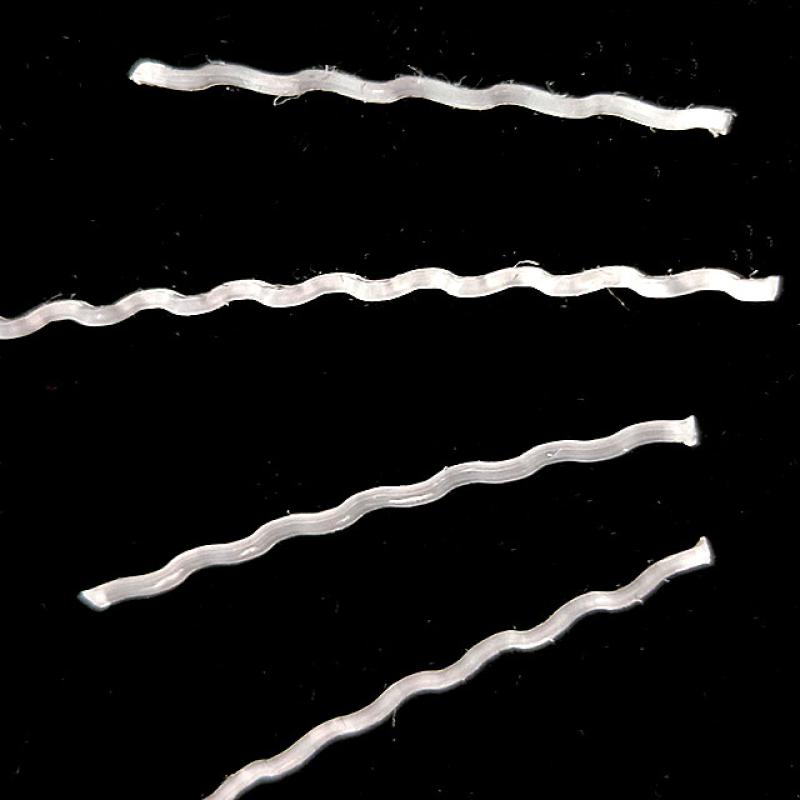

Product Details Twisted package pp fiber is developed for replacement of metallic fiber. With polypropylene as its raw material,it's far produced by way of special drawing twisting and surface remedy. Compared with metallic fiber, it has benefits of acid, alkali resistant, first rate tensile, clean dispersing, comfort for creation and no harm to the combination system. ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)38,50,54mmElastic Modulus(Mpa)>4000ColorWhite/Black/GreyEquivalent Dia(mm)0.3±0.05Material100% polypropyleneCrack Elongation(%)≥15ShapeTwi

Связаться сейчас

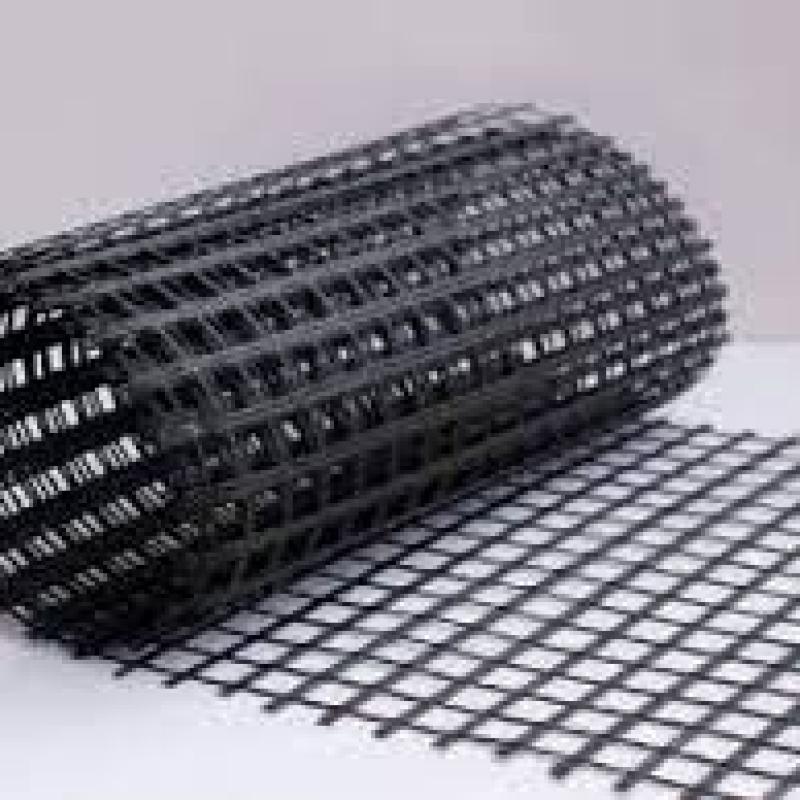

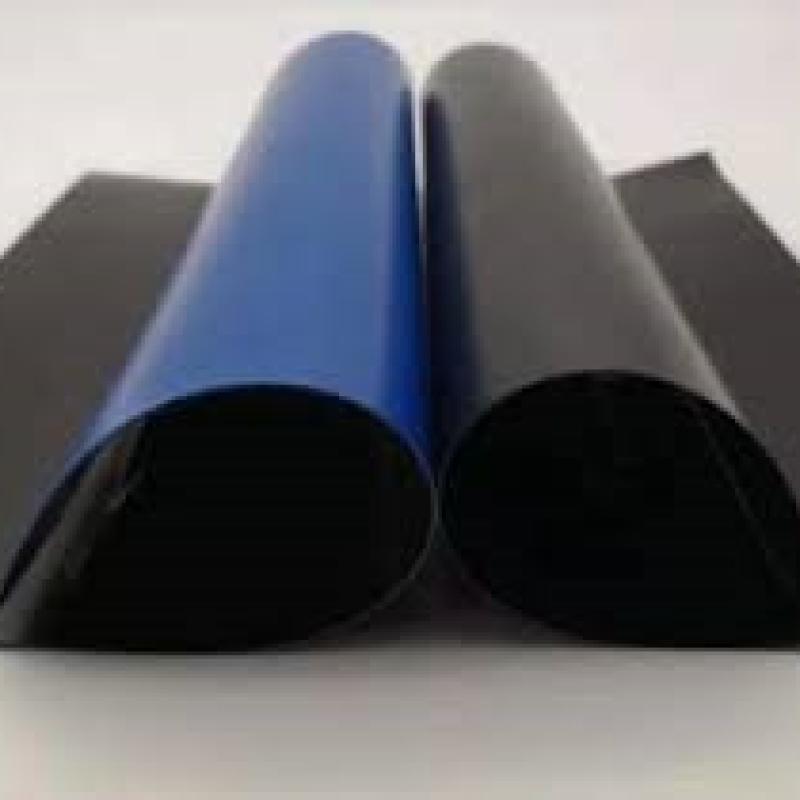

Product DetailsPlastic geogrid includes biaxial geogrid and uniaxial geogrid in keeping with its structure.Biaxial geogrid is product of polyethylene or excessive density polyethylene as the principle uncooked material thru the tactics of warm-melt extrusion, vertical and horizontal stretching to shape a excessive power reinforced square mesh shape.Uniaxial geogrid is made of high molecular polymer after extruded and laminated and punched into regular mesh before longitudinal stretching.this system makes excessive molecule in direct line country in rectangular oval net shape with uniform distr

Связаться сейчас

40 MM High Performance Structural Synthetic Macro FibersProduct Details Concrete pp fiber is made by a hundred% virgin polypropylene,adopting unique production system to make high power bundle monofilament fiber. When the fiber is positioned into the concrete,concrete (or mortar) can efficaciously manipulate concrete (or mortar) Micro-cracks which is caused by plas

Связаться сейчас

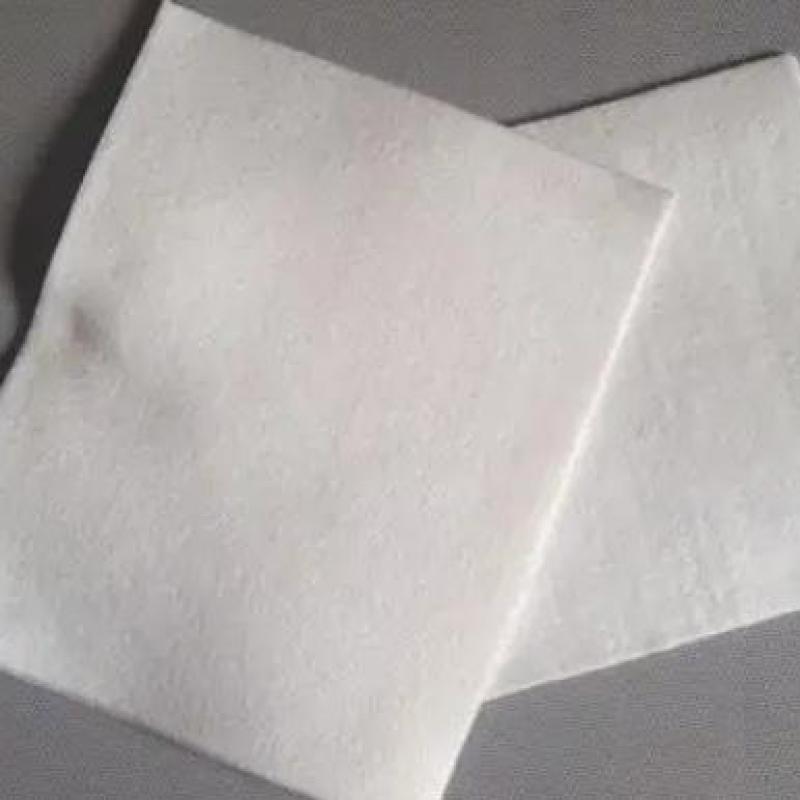

Product Details The needle-punched non woven geotextile is comprised of polyester or polypropylene fiber with the aid of unique system and era to get special thickness. Geotextiles play an critical and crucial role within the civil engineering works. The huge spectrum of geotextiles and associated products which might be to be had to civil engineers to remedy a huge variety of troubles along with their capabilities and feasible applications. Geotextiles are permeable fabric systems product of polymeric materials and are used specifically in civil engineering applications to

Связаться сейчас

PP Engineering Fiber Effectively Improves Concrete ReinforcementProduct Details With polypropylene fiber as its uncooked cloth, curved pp macro fiber is produced by using unique molding system and floor change;It has benefit of acid, alkali resistant, awesome tensile, easy dispersing, comfort for creation and no harm to automobiles and pavement and no want for special conservation. Curved pp macro fiber can be used r

Связаться сейчас

Product DetailsThat is a latent many functions substances, using this plate may be effortlessly constructed out of the overhead layer, using overhead layer shaped drainage, exhaust passage, on the same time to apply the overhead layer reaches low noise, vibration isolation function. Drainage drain board may be extensively used in the overhead layer of roofing systems, roof planting, drainage protection building basement waterproofing device, and interior floor insulation moisture safety, road and rail tunnel drainage water and so forth.Parameter NoModelNameLK-H08LK-H10LK-H12LK-H16LK-

Связаться сейчас