Synthetic PP Staple Fiber Polypropylene PP Macro Fiber for Concrete EngineeringProduct Details Concrete pp fiber is made via a hundred% virgin polypropylene,adopting unique manufacturing manner to make excessive strength bundle monofilament fiber. While the fiber is put into the concrete,concrete (or mortar) can effectively manipulate concrete (or mortar) Micro-cracks that's resulting from plastic shrinkage, temperature modifications and different elements, to save you and Inhi

Связаться сейчас

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Связаться сейчас

Fiberglass Mesh Fabric Fiberglass mesh is woven by C-glass fiberglass yarn, and then coated by alkali resistant glue.mainly has high property for acid-resistant and high strength for concrete reinforcement. Fiberglass mesh has been the main basic materials for constructions, and welcomed in Europe.1.Factory supply2.Quick delivery3.Perfect serviceFiberglass

Связаться сейчас

China Supplier Polypropylene Mesh Fiber for ConcreteProduct DetailsWhile the fiber is positioned into the concrete, the horizontal structure in fiber monofilament can be destroyed in the direction of stirring.As a result of friction and rubbing, and the fiber monofilament or internet-like form will absolutely stretch, therefore the concrete is strengthened via the usage of a brilliant amount of polypropylene fibers.ParameterDensity(g/cm³)0.91Tensile Stre

Связаться сейчас

Product Details With 100% polypropylene as raw material,Polypropylene PP fiber mesh is produced by special technology. It appears net-like structure with many mono-filament connected.

Связаться сейчас

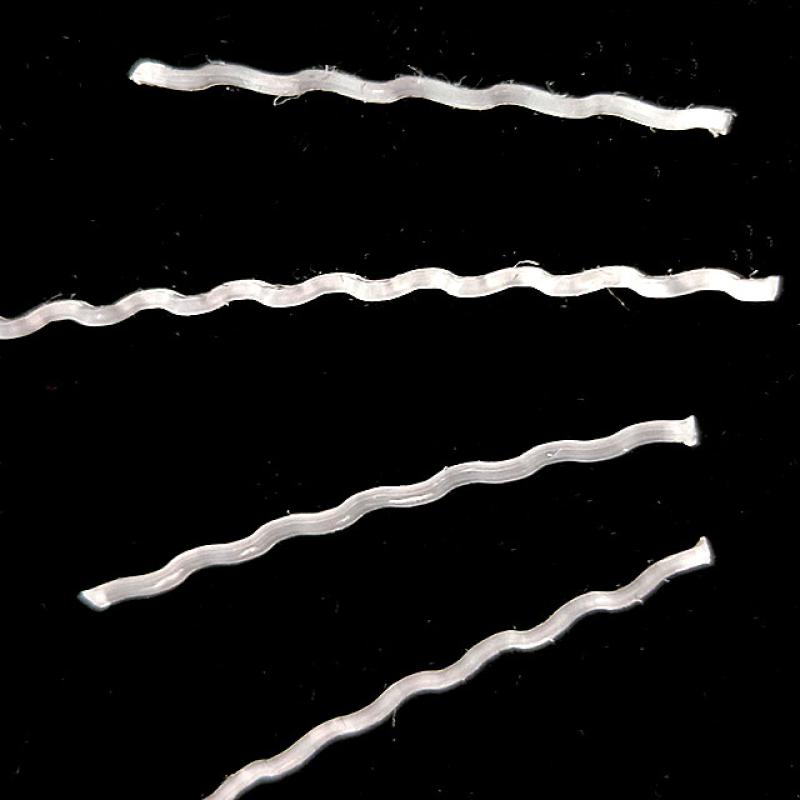

PP Engineering Fiber Effectively Improves Concrete ReinforcementProduct Details With polypropylene fiber as its uncooked cloth, curved pp macro fiber is produced by using unique molding system and floor change;It has benefit of acid, alkali resistant, awesome tensile, easy dispersing, comfort for creation and no harm to automobiles and pavement and no want for special conservation. Curved pp macro fiber can be used r

Связаться сейчас

Product Details With 100% polypropylene as raw material,Polypropylene PP fiber mesh is produced by special technology. It appears net-like structure with many mono-filament connected.

Связаться сейчас

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Связаться сейчас

Product DetailsFiberglass geogrid is made of excellent reinforcement type non-alkali glass fiber yarn which is weaved into base material by using foreign advanced warp knitting directional structure. Fiberglass geogrid can make full use of yarn textile strength to improve its chemical performance, high tension resistance, tearing resistance and creep resistance. Fiberglass geogrid system is widely used to reinforce road surface, prevent highway harm such as crack and rut from occurring, solve the problem that asphalt road surface is difficult to reinforce.ParameterItem

Связаться сейчас

Product DetailsThat is a latent many functions substances, using this plate may be effortlessly constructed out of the overhead layer, using overhead layer shaped drainage, exhaust passage, on the same time to apply the overhead layer reaches low noise, vibration isolation function. Drainage drain board may be extensively used in the overhead layer of roofing systems, roof planting, drainage protection building basement waterproofing device, and interior floor insulation moisture safety, road and rail tunnel drainage water and so forth.Parameter NoModelNameLK-H08LK-H10LK-H12LK-H16LK-

Связаться сейчас