Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Связаться сейчас

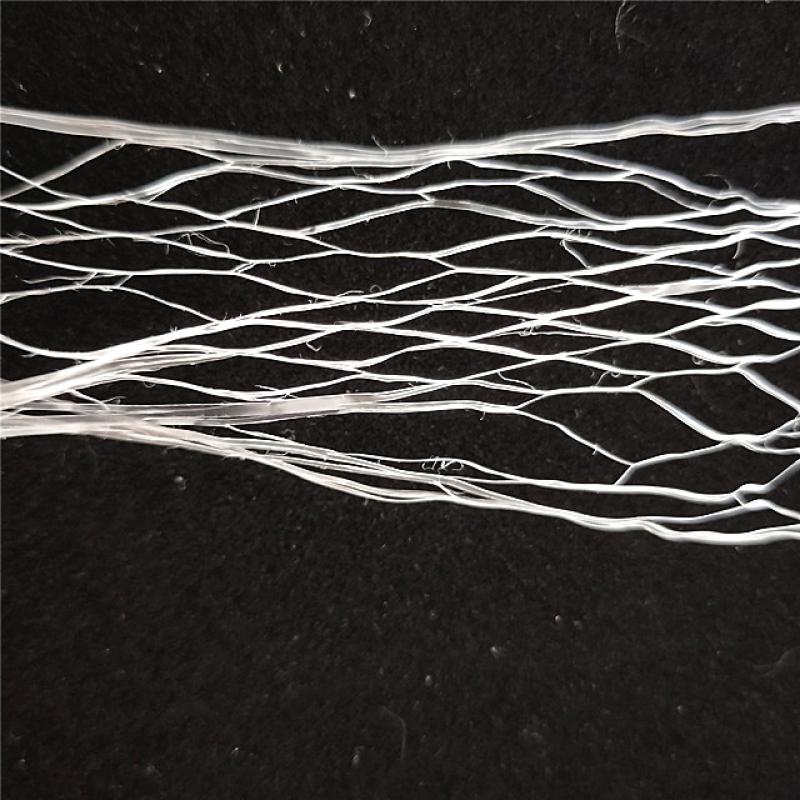

Product Details With 100% polypropylene as raw material,Polypropylene PP fiber mesh is produced by special technology. It appears net-like structure with many mono-filament connected.

Связаться сейчас

Product Details When the fiber is put into the concrete, the horizontal structure in fiber monofilament can be destroyed in the course of stirring owing to friction and rubbing, and the fiber monofilament or net-like structure will fully stretch, thus the concrete is reinforced by a great number of polypropylene fibers.ParameterDensity(g/cm³)0.91Tensile Strength(Mpa)≥ 450MpaLength(mm)6,12,18,24,36mm......Elastic Modulus(Mpa)>3500ShapeBeam-like NetEquivalent Dia(μm)100±50Material100% polypropyleneCrack Elongation(%)≥16Water-AbsorbencyNoMelting Point160-170 ℃ Feature As a new type

Связаться сейчас

Synthetic PP Staple Fiber Polypropylene PP Macro Fiber for Concrete EngineeringProduct Details Concrete pp fiber is made via a hundred% virgin polypropylene,adopting unique manufacturing manner to make excessive strength bundle monofilament fiber. While the fiber is put into the concrete,concrete (or mortar) can effectively manipulate concrete (or mortar) Micro-cracks that's resulting from plastic shrinkage, temperature modifications and different elements, to save you and Inhi

Связаться сейчас

Product Details With 100% polypropylene as raw material,Polypropylene PP fiber mesh is produced by special technology. It appears net-like structure with many mono-filament connected.

Связаться сейчас

Product Details Polypropylene fiber is likewise referred to as engineering fiber, concrete fiber, anti-crack fiber, artificial fiber or plastic fiber. We use high tenacity polypropylene resin because the raw fabric and convey with unique technical. Putting the pp fiber into concrete or mortar can manage the micro crack resulting from such elements because the plasticity contraction, air shrinkage.ParameterRaw MaterialPolypropyleneFiber TypeMonofilamentCrack Elongation(%)≥15Elasticity Modulus (Mpa)≥3500Density(g/cm³)0.91-0.93Fiber Diameter25-45μmTensile Strength(Mpa)500Melti

Связаться сейчас

Fiberglass Mesh Fabric Fiberglass mesh is woven by C-glass fiberglass yarn, and then coated by alkali resistant glue.mainly has high property for acid-resistant and high strength for concrete reinforcement. Fiberglass mesh has been the main basic materials for constructions, and welcomed in Europe.1.Factory supply2.Quick delivery3.Perfect serviceFiberglass

Связаться сейчас

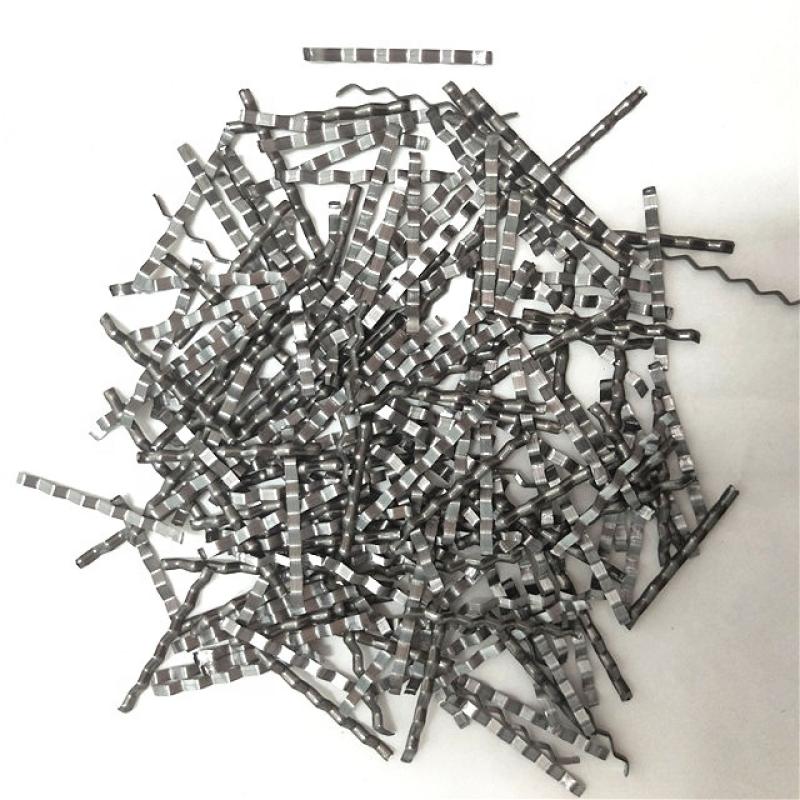

In the concrete mixture, add right amount steel fiber can be mixed into a kind of special jetting as well as casting concrete,namely Carton Steel Fiber reinforced concrete Fibers.Compared with general concrete, Carton steel fiber concrete has great improvement in tensile strength, flexural strength, abrasion resistance, impact resistance, fatigue resistance, toughness,crack resistance and antiknock performance, because large number of very minute steel fiber is evenly dispersed in the concrete and has a large contact area with concrete, therefore, concrete strength is improved i

Связаться сейчас

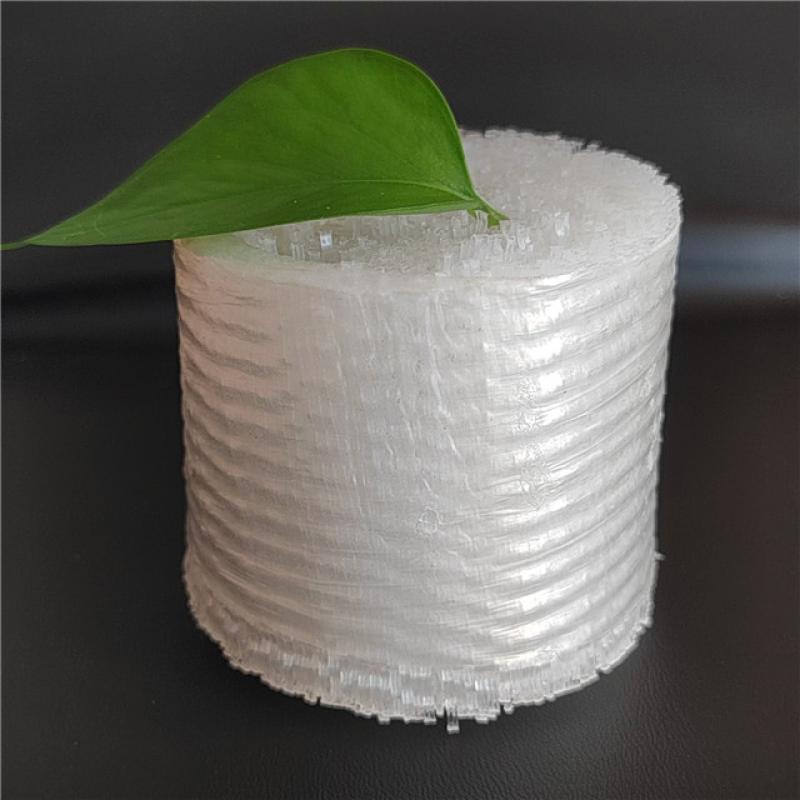

High Strength 100% Polypropylene PP Fiber for ConcreteQuality Compliance CE EN14889-2With 100% polypropylene as raw material, PP macro fiber is produced by special molding process and surface modification; it has advantage of acid, alkali resistant, excellent tensile, easy dispersing, convenience for construction and no damage to vehicles and pavement and no need for special conservation. PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete.

Связаться сейчас

Product DetailsComposite Geomembrane Liner is made by heat-bonding nonwoven or woven geotextile to HDPE geomembranes by calendaring processing technology.The composite geomembrane liner has the functions and advantages of both geotextiles and geomembranes.The geotextile layer increases essential tensile strength and the geomembranes provides excellent impermeable, leak and moisture proof.They are widely used for landfills, waste water treatment, roads construction, aquaculture, landscape and agriculture, etc.FeatureHigh tensile strength and tearing strengthExcellent seepage control, seepage pr

Связаться сейчас