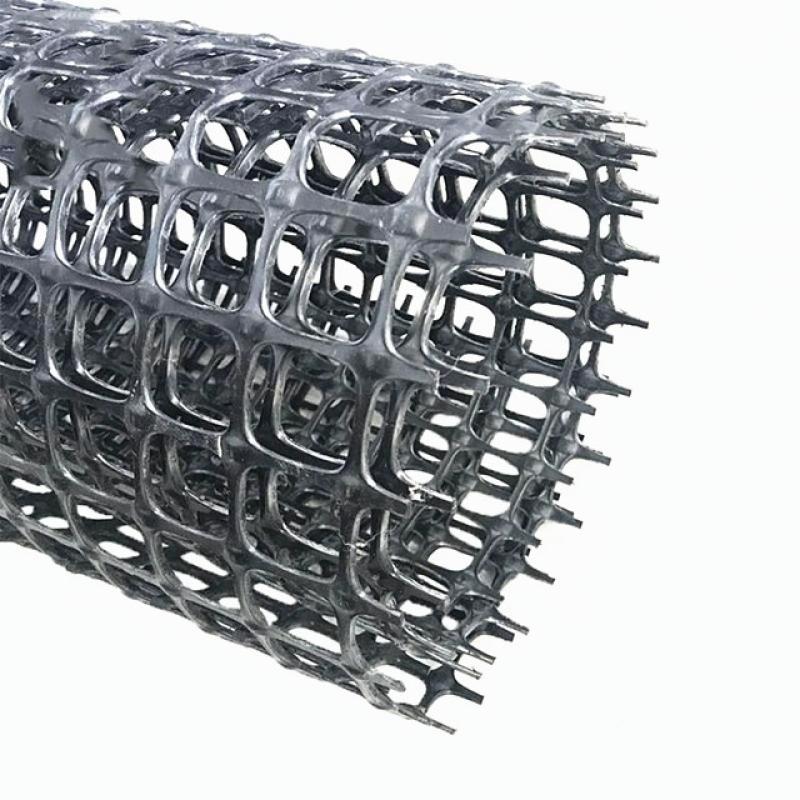

Product DetailsFiberglass geogrid is made of excellent reinforcement type non-alkali glass fiber yarn which is weaved into base material by using foreign advanced warp knitting directional structure. Fiberglass geogrid can make full use of yarn textile strength to improve its chemical performance, high tension resistance, tearing resistance and creep resistance. Fiberglass geogrid system is widely used to reinforce road surface, prevent highway harm such as crack and rut from occurring, solve the problem that asphalt road surface is difficult to reinforce.ParameterItem

Связаться сейчас

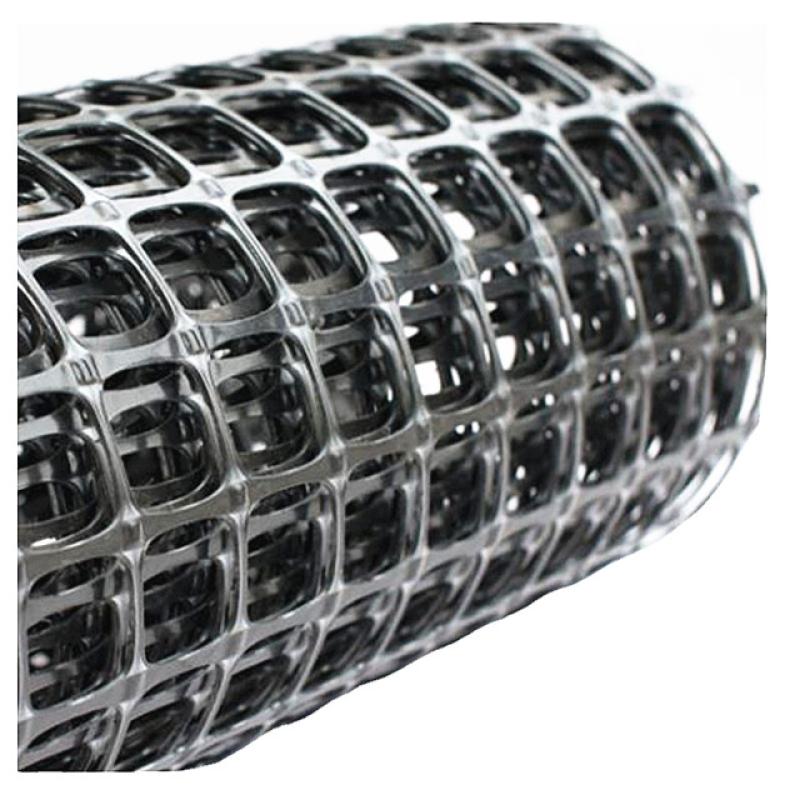

Product DetailsFiberglass geogrid reinforcement can effectively enhances the bearing capability of basis and forestalls the soil from lateral displacement because of its high friction coefficient and the bearing ability.

Связаться сейчас

Product DetailsFiberglass geogrid is manufactured from tremendous reinforcement type non-alkali glass fiber yarn that is weaved into base material by way of using overseas advanced warp knitting directional shape.

Связаться сейчас

Product DetailsSteel plastic geogrid is characterized via using high corrosion resistance and fantastic placed on resistance.

Связаться сейчас

Product information3D Reinforcement Mats Slope Greening Vegetative Blanket / 3D Mat of SoilThe strengthened geomat is pp mesh mat composited with twine mesh, that is galvanized in case of erosion manage.The shape permits enough location for maintaining the soil and grass growing. it's miles malleable to suite the shape changing, and additionally clean to install.It is able to be widely used to road mattress, rail way, slope protection, beach protection & erosion manipulate and channel.ParameterReinforce layer tech dataMaterialUnitppppStandardWeightg/m2500±50500±50EN ISO 965Melting

Связаться сейчас

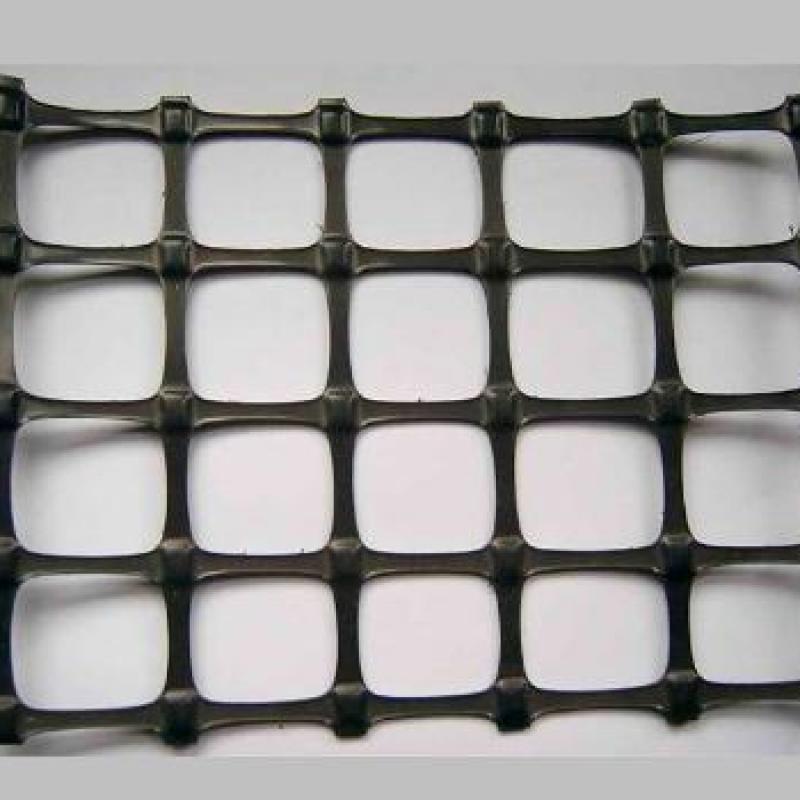

Product DetailsPlastic geogrid includes biaxial geogrid and uniaxial geogrid according to its structure.Biaxial plastic geogrid is made of polyethylene or high density polyethylene as the main raw material through the processes of hot-melt extrusion, vertical and horizontal stretching to form a high strength reinforced square mesh structure.

Связаться сейчас

Product DetailsPlastic geogrid includes biaxial geogrid and uniaxial geogrid according to its structure.Biaxial plastic geogrid is made of polyethylene or high density polyethylene as the main raw material through the processes of hot-melt extrusion, vertical and horizontal stretching to form a high strength reinforced square mesh structure.

Связаться сейчас

Product DetailsSteel plastic geogrid reinforcement can correctly enhances the bearing capacity of basis and stops the soil from lateral displacement due to its excessive friction coefficient and the bearing capability.

Связаться сейчас

Product DetailsPlastic geogrid includes biaxial geogrid and uniaxial geogrid in keeping with its structure.Biaxial geogrid is product of polyethylene or excessive density polyethylene as the principle uncooked material thru the tactics of warm-melt extrusion, vertical and horizontal stretching to shape a excessive power reinforced square mesh shape.Uniaxial geogrid is made of high molecular polymer after extruded and laminated and punched into regular mesh before longitudinal stretching.this system makes excessive molecule in direct line country in rectangular oval net shape with uniform distr

Связаться сейчас

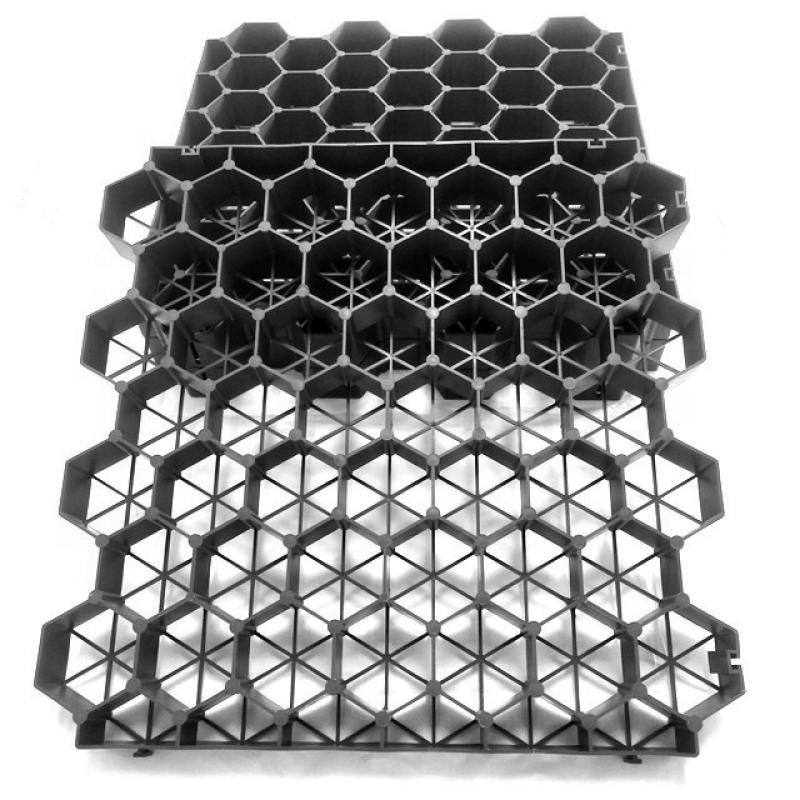

GRASS PAVERs are environmentally friendly. They are made from recycled plastic and allow the drainage of storm water back into the underground soil rather than into storm drains. This helps keep your property hydrated and reduces runoff into local sewer systems. 1. Pervious Load Bearing Surface 2. Stormwater Pollution Filtration and Treatment 3. Airborne Dust Capture and Retention 4. Heat Energy Reflection Reduction, “Cool” Surface 5. Tree Growth within Parking Areas 6. 92% Void Space for Healthy Root Development 7.100% Real Grass Coverage 8.

Связаться сейчас